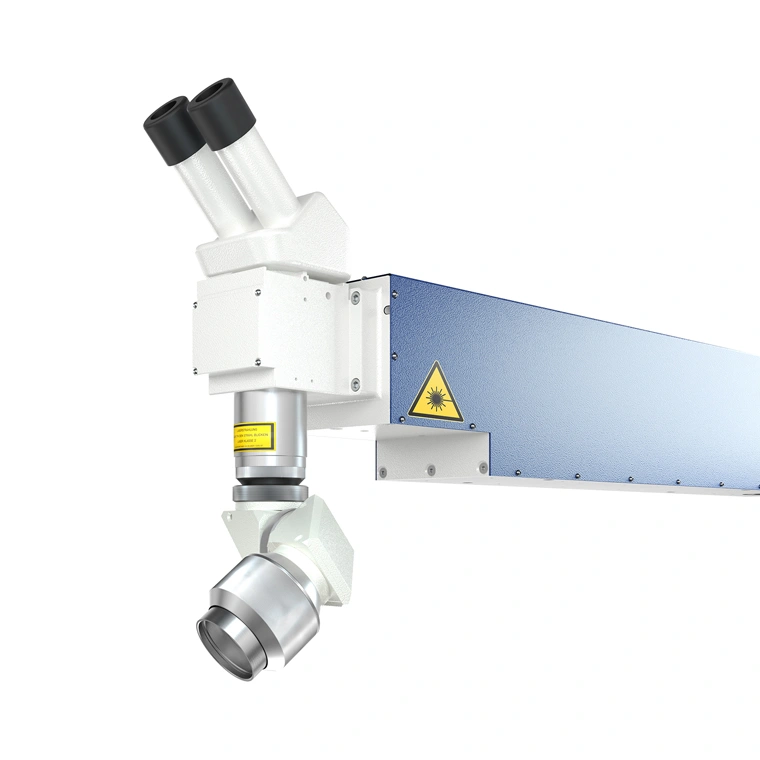

With Telescope LensSwivel Optics for Laser Welding

Full 360° Beam Control for Complex Weld Positions

The Swivel Optics module enhances your laser welding system with 360° beam deflection, enabling precision welding in hard-to-reach and non-standard positions such as vertical walls or overhead. This unit is essential for industries dealing with large, complex components and demanding geometries.

The Swivel Optics is a high-precision optical accessory engineered to tackle the challenges of laser welding in constrained or non-linear spatial environments. Whether you’re welding vertically, overhead, or at an angle, this flexible optic system gives you total control and full mobility in every direction.

With a 360° swivel range in all spatial directions, this tool ensures superior beam deflection capabilities, allowing users to access and weld even the most challenging areas on large industrial workpieces. The integrated telescope lens, available in 100 mm, 200 mm, or 300 mm focal lengths, allows users to optimize the focal point based on material thickness and joint type.

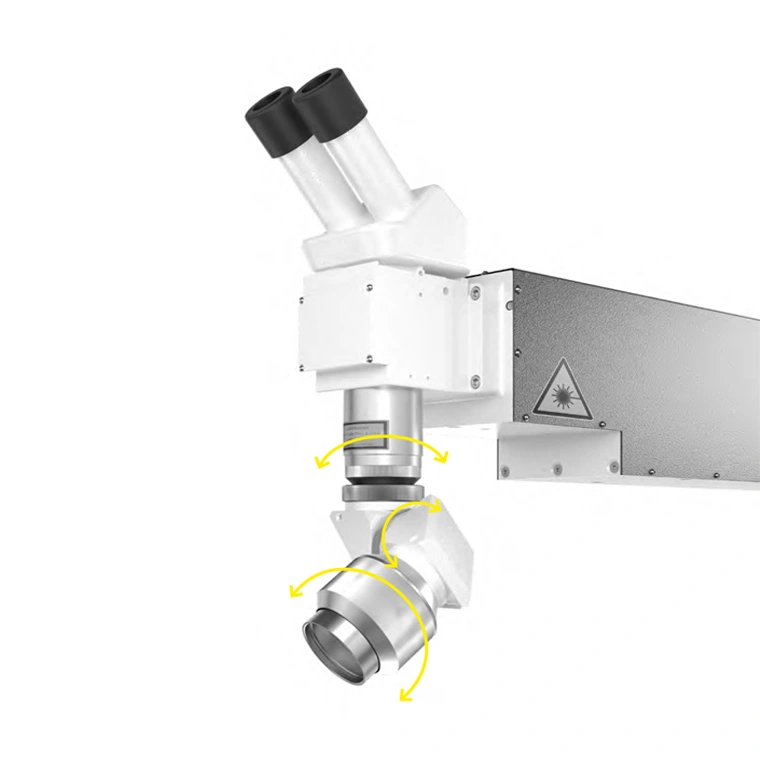

By integrating manual rotation of ±30°, the Swivel Optics head also supports the creation of fillet welds and inclined welds, making it an indispensable component for industries like aerospace, shipbuilding, and automotive manufacturing where multi-angle weld precision is a necessity.

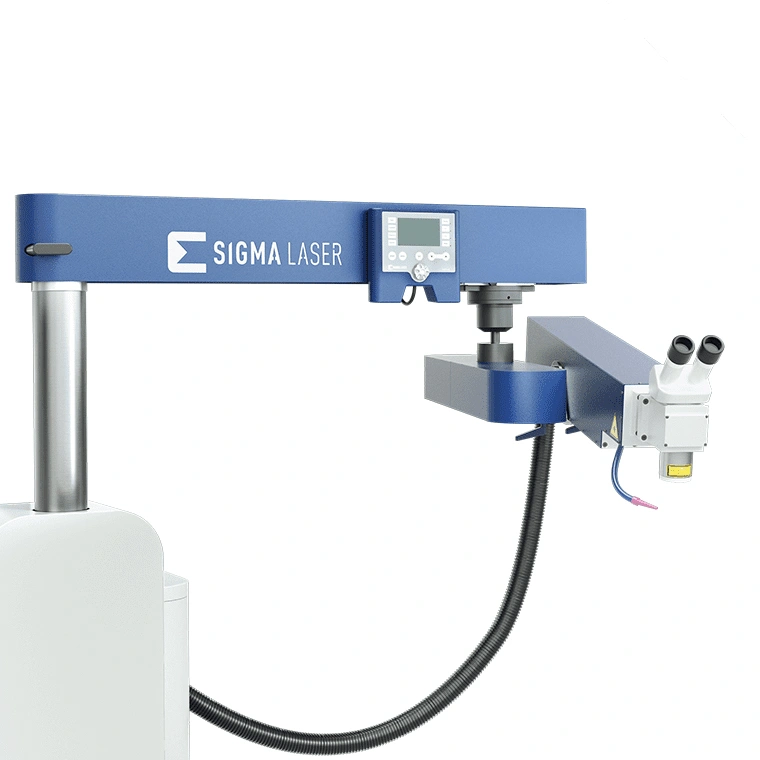

Whether upgrading an existing Sigma Laser system or adding functionality to a new one, the Swivel Optics is the perfect modular enhancement to increase flexibility, reduce repositioning time, and maintain exceptional welding accuracy in every orientation.

Engineered for Full 360° Beam ControlTechnical Specifications of Swivel Optics for Laser Welding

The Swivel Optics module is designed to provide total beam flexibility for laser welding systems. Below are the detailed technical specifications of this accessory:

Feature |

Specification |

Swivel Range |

360° rotation in all spatial directions |

Beam Orientation Control |

Manual operation via flexible optical head |

Fillet Weld Capability |

Yes – ±30° rotation of the welding head |

Focal Length Options |

100 mm, 200 mm, 300 mm telescope lenses |

Welding Angle Access |

Supports side, overhead, and angled welding positions |

Integration |

Compatible with Sigma Laser systems |

Modular Compatibility |

Fully integrates with motion units (e.g., Simass, Sidanus) |

Application Use Cases |

Large workpieces, complex geometries, vertical surfaces |

The Swivel Optics module enhances the flexibility and accessibility of laser welding processes, especially for complex geometries or hard-to-reach positions. It is a vital upgrade for manufacturers requiring multi-angle welding without repositioning the workpiece.

Beam Swiveling & Range of Motion

-

Full 360° Beam Deflection

The optics unit allows for complete rotation in every spatial direction, enabling beam alignment from any angle — ideal for working on large or complex parts. -

Manual Tilt Capability

The welding head itself can be manually rotated by ±30°, allowing for fillet welds and angled welds on vertical or overhead surfaces without adjusting the base unit.

Telescope Lens Options

-

Interchangeable Focal Lengths

Equipped with a telescopic lens system, this module supports focal lengths of 100 mm, 200 mm, and 300 mm, which allows users to optimize the laser beam focus based on workpiece size and material. -

Quick-Swap Compatibility

The lenses can be swapped easily, ensuring minimal downtime and flexibility in adapting to different project needs.

Integration & Compatibility

-

Modular System Compatibility

Seamlessly integrates with Sigma Laser systems such as Simass, Sidanus, and Sirius models — especially in setups with advanced motion units (e.g., motor-driven axes or rotating devices). -

No Additional Power Supply Needed

The module operates through existing system controls, requiring no independent electrical source.

Dimensions & Mechanical Design

-

Compact and Ergonomic Design

Designed for easy handling and minimal space requirements inside the welding chamber. -

Lightweight Construction

Ensures ease of manual adjustment during operation without fatigue, enhancing user control and positioning accuracy.

The Swivel Optics system is a high-precision, manually adjustable optical module that empowers welders to access areas previously unreachable by fixed-beam systems. With full 360-degree beam control and telescopic lens flexibility, it supports complex applications across medical devices, aerospace components, and custom fabrication.

Compatibility: Seamless Integration Across Sigma Laser Systems

The Swivel Optics module is designed with modular adaptability in mind. It integrates effortlessly into various Sigma Laser welding platforms and auxiliary motion systems, enabling greater welding flexibility without complex setup.

Compatible Systems

Laser Welding Platform |

Compatibility |

Details |

Sidanus Light |

✔️ Fully Compatible |

Allows enhanced angled welding for large workpieces. |

Sirius Light |

✔️ Fully Compatible |

Optimizes out-of-position welding on vertical surfaces. |

Siega Light |

✔️ Fully Compatible |

Ideal for overhead and difficult-to-reach joints. |

Sidanus Fibre |

✔️ Compatible |

Works with fibre-based beam paths via swivel head. |

Sirius Fibre |

✔️ Compatible |

Supports ergonomic angled welding with beam control. |

Simass Base Unit |

✔️ Modular Integration |

Manual tilt complements automation features. |

Compatible Add-On Modules

Add-On Module |

Compatibility |

Integration Notes |

Motor-Driven Z Axis |

✔️ Compatible |

Enables multi-axis flexibility. |

Swivelling Y Axis |

✔️ Highly Compatible |

Enhanced angle control when used together. |

Rotary Devices |

✔️ Compatible |

Ideal for 360° welding on cylindrical parts. |

Telescopic Lens System |

✔️ Integrated |

Lens included with Swivel Optics itself. |

Sigomatic / Sigomatic Pro |

✔️ Control Interface |

Manual beam adjustment supported via software views. |

Summary

Swivel Optics is universally compatible with all current Sigma Laser platforms and most auxiliary modules. Whether paired with light-pumped or fibre laser systems, it provides unmatched versatility for manufacturers seeking out-of-position or multi-angle welding capabilities.

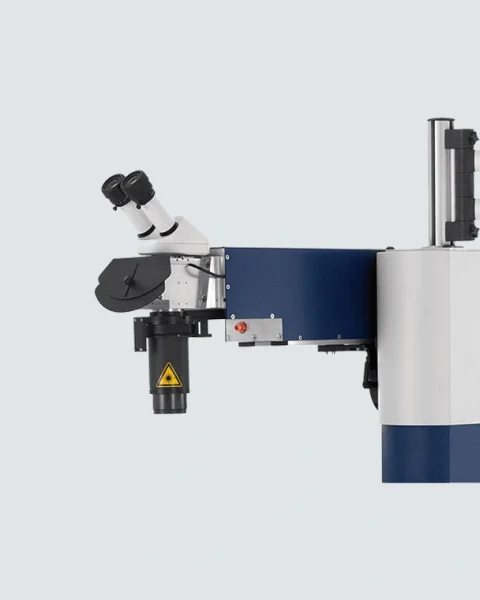

Where the Swivel Optics ExcelsIndustrial Applications of Swivel Optics in Industrial Laser Welding

Swivel Optics dramatically increases the accessibility and flexibility of laser welding systems, allowing operators to work on challenging geometries, non-horizontal surfaces, and confined spaces with high precision.

Medical Device Manufacturing

Medical devices often have intricate components with small or curved surfaces. Swivel optics allows fine beam manipulation for clean, controlled welds on medical-grade metals without needing to reposition the entire part.

Tool and Mold Repair

Swivel Optics enables precise laser beam placement inside complex tool cavities or around curved mold edges. It allows repair of hard-to-reach defects and welding in reverse angles, improving tool longevity.

Retrofit and On-Site Repairs

In maintenance and retrofit scenarios, welders often encounter limitations in space and angle. Swivel Optics allows on-the-spot angle adjustments, reducing disassembly needs and shortening repair cycles.

Shipbuilding and Structural Welding

For heavy and fixed structures where repositioning workpieces is impractical, Swivel Optics allows welders to adjust beam direction instead, enabling fillet welds, overhead joints, or vertical seams directly in place.

Electrical Housings and Enclosures

Welding inside metallic enclosures or on side-mounted fixtures is made possible by the rotating optical axis, especially for enclosure assemblies that involve multi-angle sealing or fitting.

Aerospace Component Fabrication

In aerospace, where components may feature compound curves or must be welded in-place, Swivel Optics provides vital freedom of movement to access hard-to-reach seams or angled surfaces.

Key Advantages Across Applications

- 360° accessibility to complex or confined surfaces

- No need to reposition heavy or delicate parts

- Supports fillet, inclined, or vertical welds with ease

- Perfect for high-mix, low-volume production environments

- Improves operator comfort and safety in awkward positions

Configure to Fit Your Welding NeedsCustomization Options of Swivel Optics for laser welding machines

Tailor the Optics to Your Welding Challenges

Swivel Optics can be adapted to meet a wide range of welding scenarios and part geometries. Whether you’re working on miniature components or large industrial parts, the system offers modular and customizable configurations to boost accessibility, control, and quality.

Available Customizations:

-

Telescope Lens Focal Lengths:

Choose between 100 mm, 200 mm, or 300 mm lenses depending on your working distance, focus precision, and beam spot size needs. -

Extended Swivel Range:

Fine-tune the swivel mechanism for manual or motorized control, based on your workflow — ideal for both automated and operator-guided welding systems. -

Mounting Configurations:

Flexible mounting options for various machine setups — compatible with overhead arms, fixed bases, or robotic arms. -

Material Coatings and Optics:

Upgrade to anti-reflective or dust-resistant optics for cleaner beam transmission and longer durability in challenging environments. -

Integration with Viewing Systems:

Add camera modules or laser spot indicators to support precision positioning and visual alignment before and during welding.

Optional Software & Controls:

-

Sigomatic or Sigomatic Pro Integration:

Seamlessly control swivel functions and lens adjustments through software, enabling coordinated motion with laser parameters. -

Custom Welding Presets:

Save and reuse angle-specific presets for frequent jobs, especially beneficial for repetitive tasks or specific materials.

Swivel Optics is designed not just to solve immediate access issues, but to be part of a scalable and intelligent laser welding ecosystem. By combining the right physical adjustments with software-based intelligence, it empowers operators with maximum flexibility and efficiency.

FAQsFrequently Asked Questions

Answers to common questions about the Swivel Optics for laser welding machines:

Swivel optics are designed to improve accessibility during laser welding, especially for hard-to-reach angles or overhead and vertical surfaces. They allow precise beam positioning in 360° directions, enabling high-quality welds even in challenging geometries.

Yes. Swivel optics are engineered for seamless integration and can be retrofitted to compatible laser systems without major structural changes. This makes it easy to upgrade existing setups for more flexible welding tasks.

Standard optics provide a fixed beam path, limiting weld angles. Swivel optics, however, offer multi-directional beam deflection, allowing the welding head to pivot ±30° and enabling welds on inclined or vertical planes with greater control.

Yes. The Swivel Optics system supports interchangeable telescope lenses with focal lengths of 100 mm, 200 mm, and 300 mm. This allows customization of focus distance and beam characteristics depending on the application.

While the optics can be manually operated, integration with Sigomatic or Sigomatic Pro software enables precise control, preset angles, and synchronized operation with laser settings — ideal for complex or repeatable welding tasks.

Basic training is recommended for manual operation, but full efficiency is achieved when integrated with software. With the Sigomatic interface, operators can quickly become proficient in setting up and using swivel optics for consistent results.

Helpful Guides & Articles for Swivel Optics With Telescope Lens

Best Practices for Setup, Automation, and Precision Control

This section offers practical guidance and resources to help users get the most out of their Swivel Optics system—ensuring safe, accurate, and efficient operation in demanding industrial environments.

- How to Install and Align Swivel Optics on Your Laser Welding System: A step-by-step guide for properly mounting and calibrating the swivel optics to ensure precise beam delivery and maximum accessibility during welding.

- Choosing the Right Telescope Lens: 100mm, 200mm, or 300mm? :An in-depth explanation of each focal length option and how to select the ideal lens for your specific application based on part size, working distance, and weld depth.

- Maintenance Best Practices for Long-Term Performance: Essential daily and periodic maintenance tips to keep the swivel optics clean, responsive, and mechanically sound—covering lens cleaning, rotation axis lubrication, and optical inspection.

- Troubleshooting Beam Misalignment and Tilt Angle Errors: Learn how to identify and correct beam positioning problems or inaccurate swivel angles that may affect weld quality, especially on angled or vertical surfaces.

- Optimizing Access to Difficult-to-Reach Weld Areas: Strategies and setup tips to make the most of the swivel optics’ 360° range of motion—ideal for working on complex geometries and oversized parts.

- Integrating Swivel Optics with Sigomatic Pro Software: A complete guide on connecting and configuring the swivel head with your control software for semi-automated or manual precision angle adjustments.

Long-Term Support You Can Rely OnAfter-Sales Services of Swivel Optics for laser welding machines

At Sigma Laser, our commitment to excellence doesn’t end at delivery. The Swivel Optics with telescope lens comes with a full suite of after-sales services designed to ensure optimal performance, operator confidence, and long-term value from your investment. Whether you’re a small workshop or a multinational manufacturer, our support ecosystem keeps your production running smoothly.

Performance Optimization Consulting

For customers with high-throughput needs or complex applications, we offer:

- Process auditing

- Automation optimization

- Custom software macros

- Fixture design and integration consulting

Installation & Commissioning

Our team provides on-site setup, system calibration, and full integration into your existing workspace or automation line. We ensure everything is optimized from day one — including safety checks, software configuration, and trial welds.

Spare Parts & Consumables

We maintain a well-stocked inventory of Replacement lamps, Optical components, Cooling units and Wear parts. Fast shipping worldwide ensures minimal downtime.

Remote Diagnostics & Global Support

From preventive maintenance to rapid troubleshooting, our global service team keeps your laser welding equipment running with minimal downtime through on‑site visits and secure remote diagnostics.

Operator Training & System Onboarding

Hands‑on training programs give your staff the skills to operate, maintain, and optimize Sigma laser welding systems safely and productively right from day one.

Extended Warranty & Lamp Breakage Protection

Enjoy long‑term peace of mind with comprehensive warranty coverage—including exclusive lamp break protection—for all light‑pumped laser welding systems.

Keeping Your Swivel Optics in Peak ConditionMaintenance Instructions for the Swivel Optics

Proper maintenance of the Swivel Optics system is critical to ensure long-term precision, safety, and performance. Below is a complete guide covering daily, weekly, monthly, and long-term tasks—along with expert tips.

Daily Maintenance Checklist

- Clean the telescope lens using a microfiber cloth and optical-grade cleaner.

- Check the swivel axis movement for smooth rotation and no mechanical resistance.

- Inspect beam path alignment using a visual calibration tool or test welds.

- Wipe down housing and controls to remove dust and welding residue.

Weekly Maintenance Tasks

- Lubricate swivel joints with manufacturer-recommended lubricant.

- Inspect cabling and connections for wear or overheating.

- Tighten all mounting screws and rotating mechanisms.

- Run a beam quality test to check consistency in output.

Monthly Maintenance Routine

- Full alignment check using calibration laser tools.

- Clean the internal mirror/deflector surfaces if accessible.

- Check software configuration for swivel responsiveness.

- Measure rotational angle accuracy using a test jig.

Long-Term Preventive Maintenance

- Disassemble and deep-clean swivel components every 6–12 months.

- Replace worn bearings or components showing mechanical fatigue.

- Perform full performance audit with factory specifications comparison.

- Firmware/Software updates for the control unit and Sigomatic Pro.

Pro Maintenance Tips

- Use compressed air only when optics are completely cool to avoid thermal shock.

- Avoid any solvent not explicitly marked safe for optics.

- Document all maintenance in a logbook to identify recurring issues early.

- Consider a preventive service package from Sigma Laser for in-depth calibration and tune-up.

Summary

Consistent maintenance of the Swivel Optics ensures maximum accessibility, clean beam delivery, and precise angle control for complex welding tasks. Following this checklist prolongs equipment life and reduces downtime.

Operating the Swivel Optics with ConfidenceSafety Guidelines of Swivel Optics for Laser Welding

Operating the Swivel Optics with Telescope Lens in industrial laser welding environments requires strict compliance with safety protocols to protect operators, maintain system integrity, and minimize risks during installation, operation, and maintenance.

Laser Safety Classification

The Swivel Optics is designed to be used with Class 1 or Class 4 laser systems depending on your setup:

- Ensure the optical system is fully enclosed within a Class 1 safety enclosure for maximum protection.

- When operating with open Class 4 lasers, always implement appropriate shielding and interlocks to prevent direct or scattered laser exposure.

Personal Protective Equipment (PPE)

Operators should always wear the following protective gear:

- Laser Safety Glasses: Rated specifically for the laser wavelength in use with the telescope lens.

- Protective Gloves: To safely handle optical components and hot or sharp materials.

- Anti-static Clothing or Lab Coat: To prevent contamination of delicate optical surfaces and minimize static discharge.

- Steel-toe Safety Shoes: To protect feet from heavy equipment or accidental drops.

Task |

Recommended PPE |

Routine operation |

No PPE required if system is fully enclosed |

Maintenance (open casing) |

Laser safety goggles (wavelength-specific) |

Optical adjustments |

Safety gloves, anti-static sleeves |

Handling heavy optics |

Safety shoes, cut-resistant gloves |

Cleaning or inspection |

Anti-static gloves and lint-free lens cloths |

Workspace Safety Requirements

- Clear Work Area: Keep the surroundings free of tools, cables, and loose objects to avoid tripping hazards and damage to optical components.

- Proper Ventilation: Ensure extraction systems are operational to remove welding fumes and maintain air quality.

- Stable Mounting: The swivel optics must be securely mounted on vibration-free bases for precise operation.

- Emergency Stop: Emergency stop buttons should be easily accessible to immediately halt laser operation if needed.

Electrical & Cooling System Safety

- Confirm proper grounding of the optics system and associated hardware before use.

- Regularly inspect power and signal cables for damage or wear.

- Avoid operating near liquid spills or high-humidity environments to prevent electrical hazards.

- If integrated with cooling systems, monitor coolant levels and check for leaks routinely.

Software & Control Safety

- Avoid accidental movement of the swivel optics by careful joystick or software control usage.

- Alert nearby personnel before initiating automated or continuous rotations.

- Ensure correct synchronization and communication with control software (such as Sigomatic or Sigomatic Pro) before starting operations.

Emergency Procedures

- Use the emergency stop immediately if you detect unexpected movements, smoke, sparks, or if there is any risk of injury.

- Turn off the main power before performing any inspections or maintenance.

- Follow facility evacuation procedures in case of laser or electrical emergencies.

Training & Access Control

- Only certified and trained personnel should operate or maintain the swivel optics system.

- Operators must be trained on laser safety, control interfaces, PPE usage, and workspace setup.

- Restrict access to the system using clear signage and physical barriers during operation.

Safety Summary

The Swivel Optics with Telescope Lens significantly enhances laser welding precision and flexibility, but safe operation is paramount. Strict adherence to these guidelines:

- Protects your team from laser and mechanical hazards

- Ensures longevity and reliability of your optical system

- Prevents costly downtime and operational errors

Certified training, routine inspections, and a well-organized workspace are essential to maintain a safe, efficient welding environment.

Competitive ComparisonWhy the Swivel Optics with Telescope Lens Outperforms Conventional Welding Optics?

Swivel optics are essential for laser welding in challenging or hard-to-reach positions, but not all swivel systems offer the same level of performance and flexibility. Here’s how the Swivel Optics with Telescope Lens from Sigma Laser surpasses conventional optics solutions in versatility, precision, and integration.

Full 360° Beam Deflection in All Directions

Unlike many swivel optics limited to fixed or partial angular movement, this system offers continuous 360-degree swivelling in every spatial direction. This capability dramatically improves accessibility, especially for large or complex components where traditional optics fall short.

Precision Optics with Variable Telescope Lenses

Equipped with interchangeable telescope lenses (100 mm, 200 mm, or 300 mm focal lengths), the Swivel Optics adapts to various focal requirements. This flexibility ensures optimal beam focus and weld quality across diverse applications, from fine detail work to larger surface areas.

Designed for Difficult Welding Positions

The optics enable welding out-of-position or sideways on walls and overhead — scenarios that conventional fixed optics cannot handle easily. This greatly expands your operational envelope without the need to reposition heavy components.

Seamless Integration with Sigma Laser Systems

Fully compatible with Sigma’s laser platforms and control software, the Swivel Optics integrates smoothly without complicated retrofitting or additional controllers. This guarantees reliable, synchronized operation and faster setup times.

Competitive Comparison Table:

Feature / Device |

Swivel Optics with Telescope Lens |

Conventional Swivel Optics |

Fixed Optics without Swivel |

360° Continuous Swivelling |

✅ Full range in all directions |

⚠️ Limited angle or stepwise |

❌ Not supported |

Telescope Lens Options |

✅ 100, 200, 300 mm focal lengths |

❌ Fixed or no lens options |

❌ No swivelling or zoom |

Suitable for Out-of-Position Welding |

✅ Yes |

⚠️ Limited |

❌ No |

Integration with Sigma Systems |

✅ Native, plug & play |

⚠️ May require custom setup |

❌ No native integration |

Ease of Installation |

✅ Quick and straightforward |

⚠️ Often complex |

✅ Simple but limited |

Best Use Case |

Large components, complex angles |

Moderate accessibility |

Basic linear welding tasks |

Whether upgrading existing welding optics or outfitting a new system, the Swivel Optics with Telescope Lens delivers unmatched flexibility, precision, and ease of use—perfect for modern laser welding applications that demand versatility without compromise.

Competitive Advantages of the Swivel Optics with Telescope LensWhy the Swivel Optics with Telescope Lens Is a Smart Upgrade for Precision Laser Welding Accessibility?

Unmatched Flexibility for Hard-to-Reach Welding Positions

The Swivel Optics with Telescope Lens transforms your laser welding setup by providing full 360-degree swivelling in every spatial direction. This capability enables welding at difficult angles—such as sideways on walls or overhead—where traditional fixed or limited-angle optics cannot reach effectively.

Precision Focus with Multiple Telescope Lens Options

Equipped with interchangeable telescope lenses (100 mm, 200 mm, and 300 mm focal lengths), the system offers tailored beam focusing for a wide range of applications. Whether working on fine details or large components, you can optimize weld quality and consistency with ease.

Seamless Integration with Sigma Laser Ecosystem

Designed specifically to integrate natively with Sigma’s laser platforms and control software, the Swivel Optics eliminates the need for complex retrofitting or external controllers. This ensures rapid installation, reliable communication, and synchronized operation within your production line.

Enhanced Productivity and Reduced Downtime

By enabling precise welding in out-of-position and confined spaces, this optic system reduces the need to reposition heavy workpieces or adjust fixtures repeatedly. The result is higher throughput, improved operator ergonomics, and minimized setup time.

Key Benefits at a Glance:

- Full 360° Swivelling for maximum accessibility in all spatial directions

- Multiple Telescope Lens Options for adaptable focal lengths and superior weld quality

- Out-of-Position Welding Capability to handle challenging geometries effortlessly

- Plug-and-Play Integration with Sigma laser systems and control interfaces

- Compact and Robust Design built for industrial reliability and precision

Upgrade your laser welding optics to the Swivel Optics with Telescope Lens — the smart solution for versatile, high-precision welding in complex manufacturing environments.