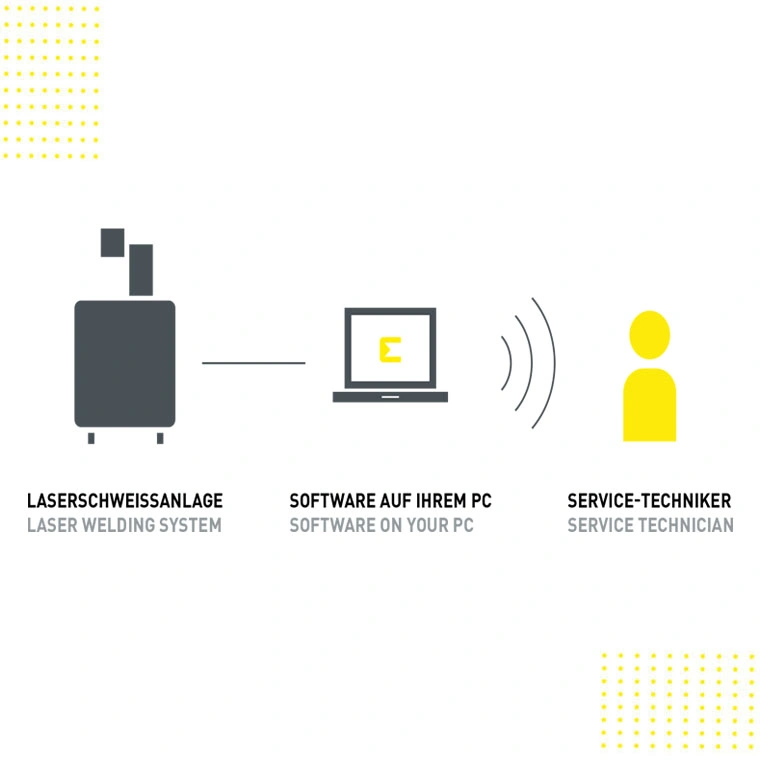

For Global SupportSigma Laser Remote Diagnosis Software

Instant Global Support Without On-Site Visits

Sigma Laser’s Remote Diagnosis Software enables real-time monitoring and troubleshooting of your laser system from virtually anywhere in the world. Save time, cut costs, and get expert support without the need for on-site service.

Sigma Laser’s Remote Diagnosis Software is a powerful tool designed to provide immediate global support for all Sigma Laser systems — without the need for on-site visits. By simply installing the software, users can grant Sigma’s technical team remote access to monitor, diagnose, and resolve issues efficiently over the Internet.

Whether you’re managing a laser system across the globe or need assistance during production, our remote service ensures minimal downtime and zero travel costs. The software monitors all critical components including electronic modules, lamp status, power supply, water quality, and safety elements. Through USB connection to the system controller, our support team can analyze and troubleshoot technical issues quickly and reliably.

Remote diagnostics help you maintain high productivity and system performance — anytime, anywhere.

Packed with advanced featuresKey Features of Remote Diagnosis Software for laser welding machines

Sigma Laser’s Remote Diagnosis Software is designed to deliver fast, efficient, and comprehensive support—no matter where your laser system is operating. By enabling real-time monitoring and analysis of all essential system components, it minimizes downtime, prevents costly failures, and eliminates the need for on-site service in most situations. Below are the standout features that make this software a vital tool for global laser system maintenance and troubleshooting.

Sigma Laser’s Remote Diagnosis Software key features are:

-

Global Remote Access

Diagnose and resolve system issues from anywhere in the world via a secure internet connection. -

Real-Time Monitoring

Continuous tracking of critical system parameters such as temperature, power supply, and cooling water quality. -

USB Controller Integration

Direct USB connectivity to the laser system controller for stable and accurate data transmission. -

Electronic Module Oversight

Monitors the status and performance of all electronic modules to detect malfunctions early. -

Lamp Status Monitoring

Keeps track of laser lamp condition to anticipate maintenance needs and prevent system failures. -

Cooling Water Quality Check

Ensures optimal performance by monitoring the condition and quality of the system’s cooling water. -

Temperature Monitoring

Tracks the temperature of electronic components to prevent overheating and extend equipment lifespan. -

Power Supply Supervision

Verifies power stability and detects anomalies that may disrupt system functionality. -

Hardware Safety Monitoring

Constantly checks the condition of safety-relevant hardware components to ensure user protection and regulatory compliance. -

No On-Site Visit Required

Reduces downtime, travel costs, and delays by eliminating the need for on-location service in most cases.

Technical Specifications of the Sigma Laser Remote Diagnosis Software

To ensure optimal performance and seamless remote connectivity, the Sigma Laser Remote Diagnosis Software requires the following technical environment:

Hardware & Software Requirements

- Compatible with Sigma Laser controller units via USB interface

- Requires a PC or laptop with:

- Minimum 4 GB RAM

- Dual-core processor (Intel i3 or higher recommended)

- At least 100 MB of free disk space

Supported Operating Systems

- Windows 10 and 11 (64-bit)

- Windows Server 2019 or later

- Not compatible with Linux or macOS at this time

Network & Connectivity

- Stable internet connection with minimum 5 Mbps upload/download speed

- Outbound internet access (port 443 or 22, depending on connection protocol)

- VPN access may be required depending on the customer’s security policies

- USB port available for controller connection

Compatibility & Integration of The Sigma Laser Remote Diagnosis Software for laser welding systems

The Sigma Laser Remote Diagnosis Software is built to seamlessly integrate into your existing laser system infrastructure while supporting a wide range of Sigma hardware and industrial protocols.

Hardware Compatibility

- Fully compatible with all Sigma Laser welding and cutting machines, including:

- Sidanus Light

- SigmaMark Series

- 4-Axis Workstations

- Supports rotary tables, motorized stages, and auxiliary modules used in industrial setups

System Connectivity

- Connects directly via USB or network interface to the machine’s main controller

- Automatic device recognition upon connection

- Secure handshake authentication for remote sessions

Industrial Standards & Protocols

- Supports industry-standard protocols such as:

- Modbus TCP/IP

- OPC UA (where applicable)

- USB CDC/Serial Communication

Designed to comply with Industry 4.0 integration principles

Industrial Applications of The Sigma Laser Remote Diagnosis Software

The Sigma Laser Remote Diagnosis Software is tailored for use across a wide range of industries where precision laser systems are essential for production, repair, or customization. Its advanced diagnostic capabilities empower maintenance teams, system integrators, and OEMs to ensure continuous performance and rapid troubleshooting of laser systems remotely and securely.

Medical Device Manufacturing

Ensure compliance and quality in the production of stainless steel and titanium medical tools, implants, and enclosures.

Toolmaking and Molds

Support the reliability of lasers in the refurbishment and modification of molds and dies, even under remote supervision.

Aerospace and Aviation

Remote troubleshooting of laser systems used for part marking, precision cutting, and repair of high-value components.

Electronics & Semiconductor

Monitor stability and performance of high-precision lasers used in PCB structuring, micro-welding, and sensor assembly.

Automotive Manufacturing

Monitor and diagnose laser welding systems used in body-in-white welding, battery module assembly, and sensor housing.

Jewelry & Watchmaking

Remote assistance for engraving, micro-welding, and cutting tasks on precious metals with minimal downtime.

UI, UXUser Interface & Experience of The Sigma Laser Remote Diagnosis Software

The Sigma Laser Remote Diagnosis Software offers a streamlined and intuitive user interface, designed to maximize productivity while minimizing the learning curve. Its interface is engineered with technicians and engineers in mind, providing quick access to all critical diagnostic and control functions.

Dashboard & Monitoring Tools

- A centralized dashboard presents a real-time overview of all connected laser systems, including system health, uptime status, and performance metrics.

- Visual indicators highlight faults, warnings, and maintenance alerts for instant recognition and response.

- Log and history sections provide deep visibility into past events and changes.

Manual & Automated Control

- Technicians can execute manual commands remotely, such as initiating system checks, adjusting key parameters, or rebooting components.

- Automated diagnostics run continuously in the background and notify users in case of any anomaly.

- Preset workflows can be configured for common troubleshooting procedures.

Remote & Mobile Access

- The software is accessible via secure remote desktop protocols, allowing experts to connect from any location with internet access.

- A responsive web-based interface or mobile companion app (if supported) enables on-the-go monitoring and basic control.

Multi-user access levels ensure role-based functionality, from monitoring-only users to full system administrators.

Customization & Scalability of The Sigma Laser Remote Diagnosis Software

The Sigma Laser Remote Diagnosis Software is designed to adapt to diverse operational environments, offering both flexibility in configuration and the ability to scale with growing industrial demands.

Customizable Settings & Profiles

- Create and manage multiple user profiles tailored to different roles (e.g., technician, engineer, supervisor).

- Customize diagnostic parameters, threshold alerts, and data reporting intervals based on production line requirements.

- Local language options and region-specific configurations enhance usability in global settings.

Scalability Across Production Lines

- Seamlessly supports multiple Sigma Laser machines within a single facility or across multiple locations.

- Efficient data management and network performance even in large-scale environments with dozens of connected devices.

- Centralized control center capability allows enterprise-wide monitoring and diagnostics.

Modular Add-Ons & Plugins

- Expand functionality through optional plugins (e.g., analytics modules, cloud synchronization, API connectors).

- Future-proof architecture enables easy integration of third-party tools and industrial automation systems.

- Regular software updates provide access to new modules and features as they become available.

Long-Term Support You Can Rely OnTraining & Support for The Sigma Laser Remote Diagnosis Software

With a comprehensive support ecosystem combining training, self-help resources, and expert assistance, Sigma Laser guarantees a smooth, productive experience with Diagnosis Software across your entire operation.

Hands-On Workshops and Webinars

Sigma Laser offers interactive workshops and live webinars designed to provide practical, hands-on experience with Sigomatic software. These sessions enable users to learn efficient programming techniques, software features, and troubleshooting tips directly from experts, accelerating skill development and confidence.

Extensive Knowledge Base and FAQs

An easily accessible online knowledge base includes frequently asked questions, troubleshooting articles, and best practice guides. This resource helps users quickly find solutions to common issues and optimizes daily operation without needing immediate support.

Proactive Maintenance and Software Upgrades

Beyond reactive support, Sigma Laser provides proactive maintenance services that include routine software health checks and scheduled updates. These ensure your Sigomatic installation stays current with the latest advancements, security patches, and performance enhancements, keeping your laser welding operations running smoothly.

Dedicated Customer Support Team

A specialized support team is available to address complex technical inquiries, provide remote diagnostics, and guide users through advanced configuration options. This ensures rapid response times and tailored assistance to minimize downtime and maximize software effectiveness.

Maintenance & Updates for The Sigma Laser Remote Diagnosis Software

Keeping your Sigma Laser Remote Diagnosis Software up to date is essential for ensuring maximum performance, system security, and long-term reliability. Our maintenance and update processes are designed with industrial continuity and data protection in mind.

Seamless Software Updates

- Regular software updates are delivered to improve performance, fix bugs, and introduce new features.

- Updates can be scheduled during non-peak hours to minimize disruption to production lines.

- Over-the-air (OTA) update capability for eligible systems simplifies the process without requiring manual intervention.

Reliable Software Maintenance & Support

- Ongoing technical support from our expert team ensures uninterrupted operation.

- Preventive maintenance tools help monitor system health and proactively detect potential issues.

- Detailed logs and diagnostics reports make troubleshooting quick and efficient.

Data Security & Compliance

- All data transfers are encrypted using industry-standard security protocols.

- User access is managed with role-based authentication to prevent unauthorized changes.

- Regular security patches keep your system protected against cyber threats and vulnerabilities.

Whether you’re operating a single workstation or a multi-facility laser system, our software maintenance services ensure consistent performance, robust security, and peace of mind.

FAQsFrequently Asked Questions

This FAQ section aims to provide quick answers to common questions, helping users maximize their experience with Remote Diagnosis Software.

Installation is straightforward. Download the software package from our official site, run the installer, and follow the on-screen instructions. Ensure your system meets the minimum hardware and network requirements for optimal performance.

The software supports Windows 10 and later versions. Compatibility with other operating systems like Linux or macOS is limited or unavailable at this time.

Remote connections are secured via encrypted protocols and require authorized login credentials. All data transmission follows industry-standard cybersecurity practices to protect your system and information.

No. Since the software relies on remote access for diagnostics, a stable internet connection is essential for real-time monitoring and support.

Check your USB connections, ensure the controller is powered on, and verify network connectivity. If issues persist, contact Sigma Laser support for assistance.

Updates can be configured for automatic download and installation or performed manually based on your preferences and production schedules.

You can reach our dedicated support team via email, phone, or through the support portal. Remote troubleshooting helps resolve most issues promptly without onsite visits.

Yes. We offer comprehensive training sessions and user manuals to help your team make the most of the software’s capabilities.

Yes. It tracks electronic modules, cooling system status, power supply, and safety elements to ensure full-system health.

Download & Licensing for The Remote Diagnosis software

Purchase and Licensing Options

The Remote Diagnosis software from Sigma Laser is available through flexible licensing models tailored to your operational needs. Licenses can be purchased directly from Sigma Laser or authorized distributors. Options include single-user licenses for small operations and enterprise licenses for large-scale production environments.

Download Links

Once your license is activated, you will receive access to the official download portal where you can securely download the latest version of the Remote Diagnosis software. All downloads are digitally signed to ensure authenticity and safety.

Trial and Demo Versions

Sigma Laser offers a trial version of the Remote Diagnosis software, allowing prospective users to explore its core features before committing to a purchase. This demo version provides limited-time access to key functionalities and is perfect for evaluating compatibility and ease of use within your workflow.

License Activation and Management

The software uses a straightforward activation process via license keys or online authentication. Users can easily manage and renew licenses through their Sigma Laser account dashboard.

Helpful Guides & Articles for the Remote Diagnosis software

To help you get the most out of Sigma Laser’s Remote Diagnosis software, we offer a comprehensive collection of guides, tutorials, and troubleshooting articles in our Knowledge Base. Whether you’re setting up the software for the first time, optimizing your remote monitoring, or resolving common issues, these resources provide clear, step-by-step instructions.

- Installing and configuring the Remote Diagnosis software

- Connecting to Sigma Laser systems remotely

- Understanding system monitoring and alerts

- Troubleshooting common connection and hardware issues

- Best practices for secure remote access and data protection

- Software updates and maintenance procedures

Competitive Advantages of Sigma Laser Remote Diagnosis Software

Sigma Laser’s Remote Diagnosis software offers unparalleled benefits that set it apart from conventional support solutions, empowering your laser welding operations with faster, smarter, and more efficient service capabilities.

Key Advantages at a Glance:

- Global Remote Access: Instantly connect to your laser system from anywhere in the world via secure internet access, eliminating costly onsite visits and reducing downtime.

- Comprehensive System Monitoring: Real-time diagnostics of all critical components including electronics, lamps, cooling systems, and safety hardware ensure early detection of potential issues.

- Seamless Integration: Designed specifically for Sigma Laser equipment, this software integrates smoothly with all system modules, providing accurate and synchronized data monitoring.

- Rapid Troubleshooting: Enables service technicians to quickly analyze and resolve faults remotely, accelerating repair times and improving overall production uptime.

- User-Friendly Interface: Intuitive controls and clear visual feedback make remote monitoring and support accessible even for operators without specialized IT skills.

- Cost Efficiency: Significant savings on travel, labor, and downtime translate into a lower total cost of ownership and better ROI on your laser systems.

- Enhanced Security: Robust encryption and access control protocols protect your system’s data and privacy during remote sessions.

By choosing Sigma Laser’s Remote Diagnosis software, you benefit from cutting-edge technology that ensures your laser welding systems stay operational and optimized with minimal disruption — keeping your production line efficient and competitive in today’s fast-paced manufacturing environment.