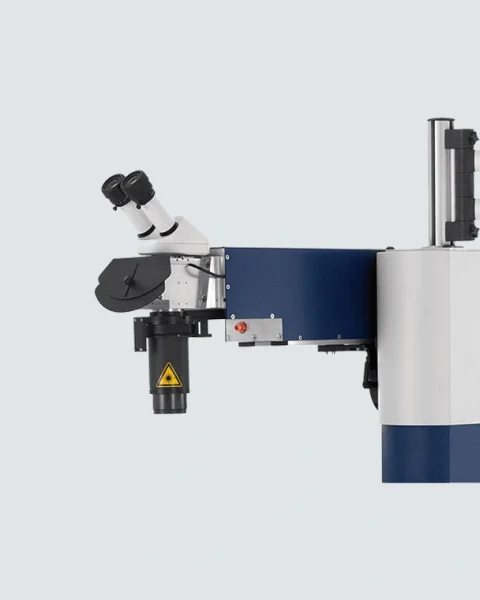

Full Process Control with Sigomatic IntegrationRemovable Magnetic Display for Laser Welding Systems

Take full control of your laser welding system with Sigma’s detachable magnetic display. Featuring 50 memory slots, integrated Sigomatic navigation, and redundant safety, it ensures simple, secure, and smart operation — all at your fingertips.

Full Control, Right Where You Need It

Simplify and streamline your welding workflow with Sigma’s Removable Magnetic Display — the intuitive control center for all Sigma laser welding systems.

Designed for flexibility and efficiency, this display mounts magnetically and connects via a 1.5-meter cable, giving you freedom of placement while keeping your setup tidy and ergonomic. Its built-in memory supports up to 50 stored welding parameter sets, making repeat jobs and quick setup changes effortless.

With seamless Sigomatic software integration, navigating through path control settings becomes faster and more intuitive than ever. Whether you’re adjusting pulse rates or reviewing machine operating hours, all data is clearly readable and instantly accessible.

This detachable display also introduces a redundant control system, enhancing reliability and reducing the risk of operation failure — especially crucial in continuous or high-precision production environments.

Key Features at a Glance:

- Up to 50 memory slots for welding parameters

- Removable magnetic mount with 1.5 m flexible cable

- Redundant control electronics for maximum reliability

- Full Sigomatic software support for smart path programming

- Live readout of pulse rate, operating hours, and more

Engineered to give operators full accessTechnical Specifications of Removable Laser Welding Display System

The Removable Laser Welding Display System is a highly efficient control and monitoring interface designed to give operators full access to welding parameters and system performance data. Built with precision and reliability in mind, this detachable unit enhances usability across all Sigma Laser welding systems.

Specifications Table

Feature |

Description |

Display Type |

Digital LCD with high-contrast readability |

Mounting System |

Magnetic holder (detachable) |

Connection Cable Length |

1.5 meters |

Memory Capacity |

50 welding parameter presets |

Redundancy |

Dual control redundancy for increased reliability |

Data Readout Functions |

Pulse rate, total operating hours, and live system feedback |

Software Integration |

Full integration with Sigomatic path control software |

User Interface |

Menu-driven UI with parameter navigation |

Power Source |

Powered through main welding system (no separate power needed) |

Weight |

~300g |

Operating Temperature Range |

0°C to 50°C |

Detailed Features

Removable & Magnetic Design

Thanks to its magnetic holder and detachable format, the display can be easily removed and repositioned during setup or operation without tools. The 1.5-meter cable gives users flexibility in placement.

50 Preset Memory Locations

Operators can save up to 50 customized welding parameter sets, ensuring consistent quality and fast setup for repeat jobs.

Real-Time Process Monitoring

Access essential data such as pulse frequency, operating hours, and system performance metrics at a glance.

Redundant Control Safety

The built-in control redundancy ensures uninterrupted operation, reducing risks during critical welding processes.

Sigomatic Software Integration

Seamlessly operates with Sigomatic, Sigma Laser’s advanced path control software, enabling intuitive navigation and parameter control directly from the display.

Intuitive Menu Navigation

An easy-to-use, multilingual interface guides the user through system settings, making training time minimal and operation efficient.

Compatibility: Seamless Integration with Sigma’s Modular Welding Systems

The Removable Display System is designed with flexibility and modularity in mind, ensuring seamless integration across a wide range of Sigma Laser’s industrial welding systems. Whether you’re working with automated setups or compact manual stations, this display unit enhances control and visibility without requiring additional configuration.

Compatible With:

Product Line |

Model Series |

Notes |

Sidanus |

Light, Ultra, Pro |

Full software and hardware compatibility |

Siega |

Light, Edge |

Direct integration with no firmware update required |

Alphaweld |

Standard, Smart |

Compatible via Sigomatic interface; auto-parameter recognition |

SigmaCore |

Industrial Modules v3+ |

Supported with magnetic mounting; full data feedback enabled |

Software Compatibility

-

Sigomatic Control Software

Native integration for real-time parameter adjustment, profile management, and diagnostics. -

Firmware Versions

Compatible with firmware v2.3 and above (Display unit auto-detects system version on boot).

Connectivity Requirements

- Cable Connector: 5-pin data + power combo

- Mounting Interface: Magnetic surface (metal-enclosed systems)

- No Additional Drivers Required – Plug-and-play functionality

Use Case Flexibility

Whether your welding station is fixed, mobile, or robotic, the Removable Display System adapts to your environment with:

- Detachable magnetic placement

- 1.5m cable range

No interference with system shielding or safety protocols

Where the Removable Display ExcelsIndustrial Applications of the Laser Welding Machine Display System

The Removable Display System enhances usability and operational flexibility across diverse industrial environments. It empowers operators with clearer visibility, faster access to welding parameters, and more intuitive control – especially in demanding production settings where adaptability and precision are essential.

Medical Device Manufacturing

In the assembly of stainless steel and titanium surgical tools, the detachable display supports cleanroom protocols by reducing machine contact and simplifying inspection.

Tool and Mold Making

In workshops where machines are tightly spaced, the detachable display can be moved closer to the welding site for quicker setup verification and visual feedback.

Aerospace & Defense

Enables safer and more ergonomic control of high-precision welds in compact fuselage sections or turbine components. Wireless functionality minimizes wiring clutter in sensitive zones.

Electronics & Battery Assembly

Improves parameter visibility during micro-welding of contacts, busbars, and PCB terminals. Allows operators to quickly adapt weld profiles without returning to the main console.

Automotive Manufacturing

Used in body assembly lines for precision laser welding of components like door frames, battery packs, and sensor housings. The removable display allows technicians to monitor real-time weld data on the go.

Custom Fabrication & Prototyping

For low-volume, high-mix production, the modular display simplifies job switching and ensures better control over non-repetitive weld cycles.

Key Advantages Across Applications

Advantage |

Description |

Mobility & Ergonomics |

Operators can position the screen wherever visibility is optimal. |

Improved Workflow Efficiency |

Reduces back-and-forth movement, especially in multi-machine environments. |

Operator Safety |

Allows distance from hot zones or enclosure doors during setup. |

Cross-Model Use |

Can be used with multiple Sigma systems on the floor. |

Adaptability in Tight Spaces |

Ideal for compact workstations and mobile welding carts. |

Configure to Fit Your Welding NeedsCustomization Options of The Removable Wireless Laser Welding Machine Display System

The Removable Display System is designed with adaptability in mind — ensuring seamless integration into diverse industrial environments and operator preferences. Sigma Laser offers various customization options to tailor the display system to your exact production needs and ergonomic requirements.

Available Customization Features

Feature |

Description |

Mounting Configuration |

Choose between magnetic base, swivel arm, or rolling stand to optimize positioning and mobility. |

Screen Size Options |

Available in 7″, 10″, or 12″ touch screens for different visibility and space constraints. |

UI Theme Customization |

Adjust UI layout, color schemes, and font sizes to suit operator preferences and reduce eye strain. |

Wireless Protocol Selection |

Supports Wi-Fi 5 / Wi-Fi 6, with optional Bluetooth fallback for environments with unstable wireless coverage. |

Button Layout Customization |

Configure hardware shortcut buttons on the display frame (e.g., emergency stop, preset selection, zoom). |

Logo & Branding |

OEM branding available for machine integrators and distributors. |

Language Support |

Multi-language interface with the ability to load custom language packs. |

Protective Casing Options |

Choose between anti-static, dustproof, or IP65-rated waterproof enclosures. |

Data Display Presets |

Customize what welding parameters (power, pulse width, frequency, etc.) are shown by default on-screen. |

Integration Flexibility

- Compatible with all Sigma Laser Welding Systems (Siega Light, Sidanus, Dione, etc.)

- Plug-and-play setup via USB-C or proprietary wireless dongle (included).

- Multiple displays can be paired with a single welding unit (admin control enabled).

- Optional docking cradle with charging and LAN passthrough available.

Custom Use Case?

If your workflow involves robotic arms, conveyor-driven parts, or cleanroom applications — our engineers can design a fully bespoke display system tailored to your unique setup.

Let us know your requirements — from hardware tweaks to UI modifications — and we’ll build a solution that fits your floor.

FAQsFrequently Asked Questions

Answers to common questions about the Detachable Control & Display Interface for Laser Welding Systems:

Yes. The display connects via secure Wi-Fi (5/6) and can operate wirelessly within a 10–20 meter range, depending on your facility’s structure. A wired fallback (USB-C) is also available if needed.

The system uses an industrial-grade lithium battery that provides up to 8 hours of continuous use on a single charge. Standby time exceeds 24 hours. A charging cradle is included for convenience.

Yes. The display is fully compatible with all current Sigma Laser welding machines, including Siega Light, Sidanus, and Dione series. Older machines may require a firmware update.

You can choose between:

- Magnetic base (for flat metal surfaces),

- Swivel arm (for flexible positioning),

-

Rolling stand (for mobile use across stations).

Mounting options can be customized based on your workspace.

- Wi-Fi 5 (802.11ac)

- Wi-Fi 6 (802.11ax)

- Optional fallback to Bluetooth 5.0 in environments with limited Wi-Fi.

- 1x Removable Display (preconfigured)

- 1x Mounting base (custom option)

- 1x Charging cradle

- 1x Wireless dongle (for pairing with main unit)

- Quick Start Guide + Accessory pack

Yes, up to 2 displays can be connected simultaneously to a single welding unit, with admin control enabled on one of them.

You can choose between standard or IP65-rated casing that is dustproof, splash-proof, and suited for demanding industrial environments.

Yes, the system supports multi-language interfaces. Custom language packs can also be uploaded if your factory requires a specific dialect or terminology.

Helpful Guides & Articles for Detachable Control & Display Interface for Laser Welding Systems

Best Practices for Setup, Automation, and Precision Control

Whether you’re new to Sigma Laser’s modules or looking to push your system to its full potential, these guides cover everything from installation to advanced automation workflows.

- How to Set Up and Install a Wireless Welding Display System

- Best Practices to Maximize Wireless Display Performance in Industrial Settings

- Guide to Mounting Your Welding Display: Magnetic, Fixed, and Custom Options

- How to Update Your Welding Display Firmware and Access New Features

- Troubleshooting Wireless Welding Display: Common Problems & Fixes

- Dual Display Setup for Welding Machines: Step-by-Step Configuration Guide

- How to Properly Clean and Maintain an Industrial Welding Display

Long-Term Support You Can Rely OnAfter-Sales Services of Laser Welding Machine Display System

At Sigma Laser, our commitment to excellence doesn’t end at delivery. The Laser Welding Machine Display System comes with a full suite of after-sales services designed to ensure optimal performance, operator confidence, and long-term value from your investment. Whether you’re a small workshop or a multinational manufacturer, our support ecosystem keeps your production running smoothly.

Performance Optimization Consulting

For customers with high-throughput needs or complex applications, we offer:

- Process auditing

- Automation optimization

- Custom software macros

- Fixture design and integration consulting

Installation & Commissioning

Our team provides on-site setup, system calibration, and full integration into your existing workspace or automation line. We ensure everything is optimized from day one — including safety checks, software configuration, and trial welds.

Spare Parts & Consumables

We maintain a well-stocked inventory of Replacement lamps, Optical components, Cooling units and Wear parts. Fast shipping worldwide ensures minimal downtime.

Remote Diagnostics & Global Support

From preventive maintenance to rapid troubleshooting, our global service team keeps your laser welding equipment running with minimal downtime through on‑site visits and secure remote diagnostics.

Operator Training & System Onboarding

Hands‑on training programs give your staff the skills to operate, maintain, and optimize Sigma laser welding systems safely and productively right from day one.

Extended Warranty & Lamp Breakage Protection

Enjoy long‑term peace of mind with comprehensive warranty coverage—including exclusive lamp break protection—for all light‑pumped laser welding systems.

Keeping Your Control & Display Interface in Peak ConditionMaintenance Instructions for the Detachable Control & Display Interface for Laser Welding Systems

Proper maintenance ensures long-term accuracy, responsiveness, and safety of your laser welding Display. Follow the checklist below to keep your device in peak condition.

Daily Maintenance

- Clean the display surface using a soft, lint-free cloth to remove dust and fingerprints.

- Check the magnetic holder to ensure secure attachment and prevent accidental drops.

- Inspect cable connections for any visible damage or looseness.

- Verify wireless signal strength to ensure uninterrupted control.

Weekly Maintenance

- Perform a system reboot to refresh software and clear temporary glitches.

- Inspect the display housing for cracks or wear that may affect durability.

- Check battery status if the display includes an internal battery or wireless power components.

Monthly Maintenance

- Update firmware and software to the latest version to benefit from improvements and bug fixes.

- Test all memory locations to ensure saved welding parameters are intact and accessible.

- Review and clean connectors thoroughly to prevent corrosion or poor contact.

Long-Term Maintenance

- Schedule calibration checks to maintain accurate readings and control.

- Replace worn or damaged cables promptly to avoid signal interruption.

- Evaluate magnetic holder strength and replace if magnetic force diminishes.

- Perform comprehensive system diagnostics in coordination with Sigma Laser technical support.

Pro Tips for Professionals

- Avoid using harsh chemicals or abrasive materials when cleaning the display.

- Keep the display away from extreme temperatures and moisture.

- Store the detachable display securely when not in use to prevent damage.

- Regularly backup welding parameters externally for recovery after resets.

Maintenance Summary

Proper maintenance of your wireless welding display system ensures optimal performance, extends device lifespan, and prevents operational interruptions. Following this structured maintenance schedule helps maintain reliability and accuracy in your welding workflows.

Operating the Wireless display system with ConfidenceSafety Guidelines of Laser Welding Machine Display System

Operating the wireless joystick and detachable display system in industrial laser welding environments demands strict compliance with safety protocols to protect users, equipment, and maintain operational integrity.

Laser Safety Classification

- These control devices are intended for use with Class 1 or Class 4 laser systems depending on your welding machine setup.

- Ensure full enclosure of the laser system for Class 1 operation or follow Class 4 laser safety procedures including shielding and interlocks when operating with open lasers.

Personal Protective Equipment (PPE)

Operators should always wear:

- Laser Safety Glasses: Rated for the specific laser wavelength in use.

- Protective Gloves: When handling hot components or during setup.

- Anti-static Clothing or Lab Coat: To reduce contamination and static discharge risks.

- Steel-toe Safety Shoes: To prevent injury from dropped tools or components.

Task |

Recommended PPE |

Routine operation |

No additional PPE under closed housing |

Maintenance (open device) |

Laser safety goggles (appropriate rating) |

Setup adjustments |

Safety gloves, protective sleeves |

Handling heavy parts |

Safety shoes, cut-resistant gloves |

Display cleaning |

Anti-static gloves, lens-safe cloths |

Workspace Safety Requirements

- Maintain a clear and organized work area free of cables, tools, and debris to prevent tripping or damage.

- Ensure proper ventilation to remove welding fumes and maintain air quality.

- The display and joystick should be placed on stable, vibration-free surfaces.

- Keep emergency stop buttons easily accessible at all times.

Electrical and Wireless System Safety

- Verify that the wireless system components are properly grounded and free of electrical faults.

- Inspect wireless connections regularly to avoid interference or signal loss.

- Avoid exposure of devices to liquids or humid environments.

- Recharge batteries and maintain wireless devices according to manufacturer guidelines.

Software and Control Warnings

- Prevent accidental joystick activation by storing it securely when not in use.

- Always alert nearby personnel before initiating automated welding processes via joystick control.

- Confirm proper synchronization with welding system software to avoid unintended commands.

Emergency Procedures

- Emergency Stop: Press immediately if unexpected movement or hazardous conditions occur.

- Power Cut: Switch off the main power before unplugging or servicing wireless components.

- Evacuation: Follow facility evacuation protocols in case of laser or electrical emergencies.

Training and Access Control

- Only trained and certified personnel should operate or maintain the joystick and display system.

- Conduct regular training covering:

- Laser system safety and control integration

- Joystick and display operation

- Proper use of PPE and workspace setup

- Restrict access to the control station with signage or physical barriers during operation.

Safety Summary

The wireless joystick and display system from Sigma Laser enhance your control capabilities but require responsible use. Following these safety guidelines ensures operator protection, preserves equipment functionality, and minimizes operational risks. Consistent training, regular inspections, and adherence to safety standards are essential for a secure and efficient laser welding environment.

Competitive ComparisonSigma Laser Wireless Display System vs. Conventional Wired Controllers?

In modern laser welding environments, precision control and user convenience are critical. Sigma Laser’s Wireless Joystick and Detachable Display system sets a new standard by combining flexibility, advanced functionality, and ease of use—without the constraints of cables.

Here’s how it compares to traditional wired joysticks and basic manual controls:

Feature / Device |

Sigma Wireless Joystick & Display |

Wired Joystick Controllers |

Manual Control Panels |

Connection Type |

✅ Wireless (Bluetooth or proprietary RF) |

❌ Wired, limited mobility |

❌ Manual, no electronic control |

Mobility & Flexibility |

✅ Full freedom of movement up to 10 m+ |

⚠️ Limited by cable length and routing |

❌ Fixed at control panel |

Control Functions |

✅ Multifunctional: pulse control, 4th axis, programmable keys |

⚠️ Limited multifunctionality |

❌ Basic or no programmable features |

Ease of Installation |

✅ Plug-and-play, no cable management issues |

⚠️ Requires cable routing and mounting |

✅ Simple but limited in control |

Display Integration |

✅ Detachable magnetic display with data readout |

⚠️ Typically fixed or no display |

❌ No digital display |

Compatibility with Sigma Systems |

✅ Fully integrated |

✅ Generally compatible |

⚠️ Limited integration |

Durability & Reliability |

✅ High, with wireless encryption and redundancy |

⚠️ Cable wear and potential connection faults |

❌ Mechanical wear |

User Convenience |

✅ Ergonomic, wireless, and modular |

⚠️ Restricted movement |

❌ No ergonomic design |

Best Use Case |

Automated, flexible laser welding setups |

Semi-automated, fixed stations |

Basic manual welding tasks |

Whether you need greater operator mobility, advanced programmable controls, or a clean setup free from cable clutter, the Sigma Wireless Joystick and Display system delivers superior performance and usability, making it the smart choice for modern laser welding operations.

Competitive AdvantagesWhy choose the Sigma Laser Wireless Joystick and Display System?

Seamless Wireless Control for Maximum Flexibility

In laser welding, operator freedom and precision are essential. The Sigma Wireless Joystick and Detachable Display system offers unmatched mobility without the hassle of cables, enabling welders to position themselves optimally for every job. This freedom significantly enhances control accuracy and comfort, translating directly into higher-quality welds.

Multifunctional and User-Centric Design

Equipped with advanced functions such as automatic pulse control, integrated fourth-axis management, and programmable keys, the joystick streamlines complex welding operations. The detachable magnetic display provides instant access to crucial process data and parameter memory, making system monitoring and adjustments quick and intuitive.

Plug-and-Play Integration with Sigma Systems

Designed specifically for Sigma Laser’s manual welding machines, the wireless joystick and display integrate flawlessly with existing hardware and software ecosystems—no additional setup or configuration is needed. This seamless compatibility reduces downtime and accelerates deployment.

Key Benefits at a Glance:

- Wireless Freedom: No cables, no restrictions—operate comfortably anywhere within range.

- Comprehensive Control: Manage pulse settings, rotation axis, and more directly from the joystick.

- Ergonomic and Modular: Detachable display with magnetic holder and user-friendly interface.

- Reliable and Secure: Wireless communication with encryption ensures stable and safe operation.

- Enhanced Productivity: Faster positioning, smoother workflow, and reduced operator fatigue.

- Wide Industry Applicability: Ideal for automotive, aerospace, tool manufacturing, and precision engineering.

Upgrade Your Laser Welding Experience

Unlike conventional wired joysticks or basic manual panels, the Sigma Wireless Joystick and Display system was engineered for ease of use, adaptability, and professional-grade performance. Investing in this upgrade means smoother workflows, higher precision, and the freedom to work smarter—without compromise.