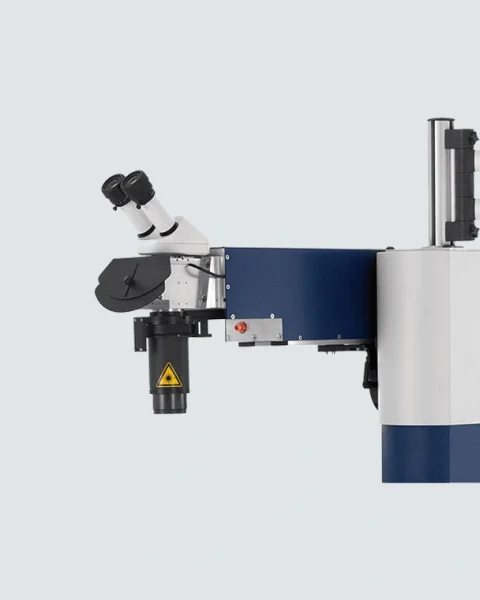

Precision and Control in Your HandsFlexible Joystick SigmaMax for Laser Welding Systems

Experience unmatched control and precision with Sigma Laser’s multifunctional joystick – designed for seamless manual operation, real-time axis control, and enhanced user comfort across all our laser welding systems.

The Sigma Laser flexible joystick is a high-performance control accessory designed to bring unparalleled precision, speed, and convenience to manual laser welding operations. Whether you’re switching between analogue and digital modes, activating a rotation axis, or customizing input functions, this multifunctional joystick puts complete system control at your fingertips.

Built based on continuous feedback from our users, the joystick offers application-specific features that enhance day-to-day welding tasks. It seamlessly integrates with all manual laser welding systems from Sigma Laser, allowing for modular customization based on operator needs.

Key Features & Functions:

- Analogue and digital operation modes – Switch easily based on your workflow

- Jog-off function – For safer operation and control

- Vmax function – Enables rapid movement and positioning of the laser head

- Coordinate invert function – Simplifies mirror welding or complex geometry handling

- Integrated fourth-axis control – Full support for motorized rotation devices

- Freely programmable buttons – Personalize the interface for recurring tasks

- Automatic pulse control – For consistent and repeatable weld quality

Designed for ergonomic performance and intuitive control, the Sigma Laser joystick ensures that welders can operate their systems with maximum efficiency and comfort. From the detachable magnetic display to user-defined key mapping, every aspect of the joystick promotes user-friendliness and flexibility.

This joystick is an essential upgrade for any manual laser welding station looking to improve precision handling and operational speed.

Engineered to give operators full commandTechnical Specifications of Joystick SigmaMax

Precision Meets Flexibility in Control

The Flexible Joystick is engineered to give operators full command over Sigma Laser’s manual laser welding systems. From analog/digital switching to integrated fourth-axis rotation, this accessory delivers industrial-grade performance with user-centric customization options. Whether you’re working on high-precision tasks or need rapid positioning, this joystick empowers you with intuitive control.

Feature Overview

Feature |

Description |

Operation Modes |

Supports both analog and digital control modes |

Jog-off Function |

Enables quick disengagement from current movement for manual correction |

Vmax Function |

Rapid positioning capability for high-speed axis movement |

Coordinate Inversion |

Allows instant flipping of movement direction for improved flexibility |

4th Axis Control |

Built-in control for motor-driven rotation devices |

Programmable Buttons |

Custom assignable buttons for user-defined functions and shortcuts |

Automatic Pulse Control |

Synchronizes laser pulses automatically with motion sequences |

Modular Compatibility |

Integrates seamlessly with Sigma Laser’s modular display and accessories |

User Comfort Design |

Ergonomic build for long sessions of manual welding |

Feature Highlights

Dual Operation Modes

Switch effortlessly between analog and digital operation depending on your workflow requirements – ideal for both delicate tuning and fast adjustments.

Jog-Off Function

Temporarily halt the system motion for precise manual repositioning, without interrupting your workflow.

Vmax Function

This function enables high-speed repositioning of the welding head, significantly reducing cycle time on repetitive tasks.

Coordinate Inversion

Quickly invert control directions to accommodate complex part orientations or customized fixture setups.

Integrated 4th Axis Control

No additional hardware required – directly operate a motor-driven rotary axis for circumferential welds or rotating components.

Customizable Buttons

Assign frequently-used operations to programmable keys, optimizing your control interface to fit your exact needs.

Automatic Pulse Management

This smart integration automates laser pulsing based on joystick movement, improving weld consistency and precision.

Modular & Ergonomic Design

Designed to work perfectly with other Sigma Laser modules such as magnetic displays, while offering comfortable handling even during extended operations.

Compatibility: Seamless Integration with Sigma’s Modular Welding Systems

The Flexible Joystick is engineered to seamlessly integrate with all manual laser welding systems from Sigma Laser. It enhances operator control with precision navigation, intuitive axis handling, and a suite of programmable functions. Thanks to its plug-and-play modular design, the joystick can be added to most systems without retrofitting, offering advanced control capabilities right at your fingertips.

Compatible With:

Laser System |

Compatibility Level |

Notes |

Sidanus Light |

✅ Fully Compatible |

Enables full manual control with 4th axis activation and pulse settings. |

Sirius Light |

✅ Fully Compatible |

Ideal for intricate operations with jog and Vmax functionality. |

Siega Light |

✅ Fully Compatible |

Optimized for precision tasks using programmable key features. |

Sidanus Fibre |

✅ Fully Compatible |

Smooth integration for hybrid analog/digital control. |

Sirius Fibre |

✅ Fully Compatible |

Enhanced operator interface for complex welding sequences. |

Simass Base Unit |

✅ Fully Compatible |

Easily mounted and configured as part of the modular control suite. |

Simass Slide |

✅ Compatible (with mount adapter) |

Recommended for use with auxiliary holder. |

Simass Rotate |

❌ Not Required |

Built-in interface includes joystick-like control. |

The Flexible Joystick is a vital component for users seeking responsive, ergonomic, and fully customizable control of their laser welding workflow — whether in industrial prototyping or precision manufacturing environments.

Where the Joystick ExcelsIndustrial Applications of the Laser Welding Joystick Controllers

The Flexible Joystick brings a new level of ergonomic precision and responsiveness to manual laser welding systems, making it indispensable across industries that demand fine control, flexibility, and user-defined command sequences. From medical engineering to aerospace fabrication, its integration streamlines manual tasks and enhances operator confidence, especially in delicate or high-complexity welding scenarios.

Medical Device Manufacturing

Used for welding surgical tools, endoscopic components, and implantable devices where micro-level accuracy is essential. The joystick enables intuitive movement and fine positioning for delicate welds.

Tool and Mold Making

Ideal for precision welding of molds, dies, and repair of worn industrial tools. Operators can use multi-axis jogging to follow complex contours with minimal effort.

Jewelry and Watch Industry

Supports ultra-fine manual welding of precious metals and intricate mechanisms. The programmable buttons allow operators to switch between spot and seam modes without moving hands off the work zone.

Electrical & Sensor Housings

Used for assembling sensors, battery tabs, and micro connectors. The joystick enhances handling of delicate assemblies with quick access to laser control parameters.

Automotive Prototyping & Repair

Used for manual welding of custom brackets, exhaust components, and sensor housings during prototype development or low-volume production. The joystick supports dynamic adjustment of pulse parameters during the welding process.

Aerospace Components

Facilitates manual touch-up and precision rework on turbine blades, fuel lines, and structural joints. It allows smooth navigation even on complex geometries with high-heat control demands.

Key Advantages Across Applications

- Ergonomic Precision: Reduces fatigue during long manual sessions.

- Programmable Functions: Quick access to laser settings, jog modes, and axis switching.

- Multi-System Compatibility: Seamlessly integrates with a wide range of Sigma Laser systems.

- Enhanced Operator Confidence: Improves weld quality and repeatability with fine motor control.

- Workflow Optimization: Reduces downtime and increases output in manual welding environments.

Configure to Fit Your Welding NeedsCustomization Options of The laser welding Flexible Joystick SigmaMax

Every production environment has its unique challenges—and the Flexible Joystick is designed to adapt. Whether your team needs simplified control schemes for ease of training or advanced programming options for complex workflows, this joystick can be customized to meet your exact operational needs.

Available Customization Features

1. Programmable Button Mapping

Assign critical functions such as laser trigger, power adjustment, jog axis switching, and pulse mode toggling to the joystick buttons based on operator preference or production needs.

2. Sensitivity & Movement Scaling

Customize the responsiveness of each joystick axis to suit different applications—fine control for micro-welding, or rapid motion for larger structural work.

3. Axis Lock & Direction Inversion

Individually lock axes or invert movement directions to match your preferred control logic or accommodate specific part orientations.

4. Preset Profiles

Create and save multiple user profiles for different operators or jobs. Switch between them instantly to streamline setup and minimize errors.

5. Integration Settings

Choose from USB, serial, or proprietary connector options to ensure smooth integration with different Sigma Laser controllers or custom system architectures.

6. Mounting & Housing Options

Select from various mounting kits (desktop, arm-mounted, magnetic base) and protective casings suitable for cleanroom, factory, or mobile environments.

Tailored for Your Workflow

Whether you’re operating in aerospace prototyping or jewelry micro-welding, the Flexible Joystick can be configured to align with your workflow. Our engineering team also supports custom firmware modifications for high-volume clients requiring non-standard behavior, safety interlocks, or system-specific command protocols.

Contact us to discuss your use case and explore how we can tailor the joystick to your exact requirements.

FAQsFrequently Asked Questions

Answers to common questions about the Flexible Joystick of laser welding machines:

Yes, the joystick is natively compatible with all Sigma Laser controller models. For older systems, an adapter or firmware update may be required—please contact support for confirmation.

You can easily remap joystick buttons via the Sigma Laser control software. A step-by-step guide is available in our Knowledge Base. No coding or technician is required.

First, check the connection cable and power status. If the issue persists, restart the control software. For further troubleshooting, refer to our diagnostic guide or contact technical support.

Yes, the Flexible Joystick is wireless.

Yes, the joystick supports full multi-axis control, including rotational (C-axis), depending on your machine’s configuration and control permissions.

Absolutely. You can create and save multiple user profiles with different button mappings, sensitivity levels, and axis behaviors. Switching profiles is instant and can be password-protected.

Calibration is rarely needed, but if performance drifts, you can access the calibration settings via the joystick management interface in the control panel. Instructions are provided in the setup manual.

Yes, it is built with industrial-grade materials, has an IP-rated enclosure (depending on model), and offers optional protective housing for harsh environments.

Helpful Guides & Articles for laser welding joystick and controllers

Best Practices for Setup, Automation, and Precision Control

Whether you’re new to Sigma Laser’s modules or looking to push your system to its full potential, these guides cover everything from installation to advanced automation workflows.

- Getting Started with the Flexible Joystick

A step-by-step guide to setting up and configuring your joystick for the first time. -

How to Remap Buttons and Customize Controls

Learn how to personalize button functions and axis sensitivity for different users or applications. -

Troubleshooting Joystick Connectivity Issues

Identify and resolve the most common hardware and software-related problems. -

Optimizing Multi-Axis Control with the Joystick

Maximize productivity and precision with expert tips on using the joystick across X, Y, Z, and C axes. -

Joystick Calibration & Maintenance Guide

Ensure long-term accuracy and reliability with this comprehensive calibration and care guide. -

Firmware Updates & Compatibility Checks

Stay up to date with the latest software updates and ensure full system compatibility.

Long-Term Support You Can Rely OnAfter-Sales Services of Flexible Joystick and laser control system

At Sigma Laser, our commitment to excellence doesn’t end at delivery. The Flexible Joystick and laser control system comes with a full suite of after-sales services designed to ensure optimal performance, operator confidence, and long-term value from your investment. Whether you’re a small workshop or a multinational manufacturer, our support ecosystem keeps your production running smoothly.

Performance Optimization Consulting

For customers with high-throughput needs or complex applications, we offer:

- Process auditing

- Automation optimization

- Custom software macros

- Fixture design and integration consulting

Installation & Commissioning

Our team provides on-site setup, system calibration, and full integration into your existing workspace or automation line. We ensure everything is optimized from day one — including safety checks, software configuration, and trial welds.

Spare Parts & Consumables

We maintain a well-stocked inventory of Replacement lamps, Optical components, Cooling units and Wear parts. Fast shipping worldwide ensures minimal downtime.

Remote Diagnostics & Global Support

From preventive maintenance to rapid troubleshooting, our global service team keeps your laser welding equipment running with minimal downtime through on‑site visits and secure remote diagnostics.

Operator Training & System Onboarding

Hands‑on training programs give your staff the skills to operate, maintain, and optimize Sigma laser welding systems safely and productively right from day one.

Extended Warranty & Lamp Breakage Protection

Enjoy long‑term peace of mind with comprehensive warranty coverage—including exclusive lamp break protection—for all light‑pumped laser welding systems.

Keeping Your laser control system in Peak ConditionMaintenance Instructions for the Flexible Joystick and laser control system

Proper maintenance ensures long-term accuracy, responsiveness, and safety of your Flexible Joystick. Follow the checklist below to keep your device in peak condition.

Daily Maintenance

- Wipe the joystick and button surfaces with a clean microfiber cloth.

- Visually inspect for dust, debris, or spills around the base.

- Ensure smooth movement on all axes (X, Y, Z, C).

- Check for any loose connections in the USB or interface cables.

Weekly Maintenance

- Blow out any accumulated dust using dry compressed air.

- Verify that the joystick springs back to center without lag.

- Confirm LED indicators and button responsiveness.

- Test button remapping and custom profiles for consistency.

Monthly Maintenance

- Check for firmware updates via Sigma Laser control software.

- Inspect the cable for wear or bending at stress points.

- Re-calibrate the joystick if slight drift or misalignment is detected.

- Verify correct behavior of advanced axis switching (dual mode or toggle functions).

Long-Term Maintenance (Every 6–12 Months)

- Perform full diagnostic tests through the system dashboard.

- Replace protective rubber caps if worn out (especially in harsh environments).

- Inspect internal circuitry for corrosion or moisture damage (only by certified personnel).

- Review user feedback logs to identify long-term performance degradation.

Pro Tips for Advanced Users

- Store backup profiles for different operators or materials.

- Use custom dead zone settings to improve micro-motion control in precision welds.

- Assign shortcut macros to buttons for repetitive multi-axis movements.

- Avoid over-tightening the mounting base to preserve gimbal sensitivity.

Maintenance Summary

- Clean and inspect daily

- Dust and test responsiveness weekly

- Update, calibrate, and inspect cables monthly

- Run diagnostics and deep checks biannually

- Apply pro-level tweaks for high-precision workflows

Regular care of the Flexible Joystick will ensure unmatched responsiveness, reduce system downtime, and extend the lifetime of your device in demanding industrial environments.

Operating the Wireless Joystick with ConfidenceSafety Guidelines of Wireless Joystick and laser control system

Using the Joystick Controller in industrial laser welding environments demands strict adherence to safety protocols. These guidelines ensure safe operation, prevent accidents, and maintain the longevity of both the controller and the connected systems.

Electrical & Handling Safety

- Power Supply: Ensure the joystick is connected to the designated power source with correct voltage and polarity.

- Static Discharge: Avoid touching internal circuits without anti-static protection to prevent damage to sensitive electronics.

- Dry Environment: Never operate or store the joystick in high-humidity or liquid-prone environments.

Operational Safety

- Boot-Up Calibration: Avoid applying force to the joystick lever during system startup to prevent misalignment.

- Unintentional Activation: Before turning on the main system, ensure the joystick is in the neutral (centered) position.

- Delayed Response Awareness: Account for slight system delays in motor or laser reaction after joystick input.

Personal Protective Equipment (PPE)

Most joystick operations are performed in safe zones or under enclosed systems, but in case of direct interaction with machinery:

Task |

Recommended PPE |

Basic system operation |

No PPE required under normal conditions |

Maintenance involving live signals |

Anti-static gloves |

Calibration with exposed machinery |

Safety glasses, gloves, long sleeves |

Wiring or cable replacements |

Insulated gloves, anti-static wristband |

Workspace Safety Requirements

- Ergonomic Placement: Position the joystick on a stable, easy-to-reach surface to avoid fatigue and accidental drops.

- Emergency Access: Maintain clear access to system-wide E-STOPs near the controller station.

- Labeling: Ensure joystick movement directions are clearly labeled (X/Y/Z/C or custom axes).

Software & System Integration

- Axis Mapping Confirmation: Always confirm the joystick axes are mapped correctly to the corresponding motors before use.

- Firmware Updates: Only update joystick firmware through approved Sigma Laser tools to avoid control errors.

- Sigomatic Integration: Ensure proper communication between the joystick and Sigomatic/Sigomatic Pro controllers.

Emergency Procedures

- Unexpected Movement: If the machine behaves erratically, release the joystick and press the main E-STOP immediately.

- Signal Loss: If connection to the system controller is lost, power down the joystick and recheck cable integrity.

- Power Cut: Always turn off the system before unplugging or relocating the joystick.

Training & Access Control

- Trained Personnel Only: Only certified staff should operate the joystick for live welding or motion tasks.

-

Onboarding: New operators must undergo training that includes:

- Safe handling of motion controllers

- System integration steps

- Emergency protocols

- Access Control: Secure the joystick station during inactive hours to prevent unauthorized use.

Safety Summary

The Joystick Controller is a precise and responsive tool designed to improve manual control of your welding system. Following the above safety guidelines:

- Minimizes risk of motion-related accidents

- Protects system integrity

- Enhances operational confidence

Prioritizing training, safe handling, and careful system integration is key to a productive and hazard-free laser welding workflow.

Competitive ComparisonSigma Laser Wireless Joystick SigmaMax vs Traditional Wired Joysticks?

When it comes to operator control in precision laser welding and automation systems, the input device plays a crucial role in user comfort, accuracy, and workflow efficiency. The Sigma Wireless Joystick stands out by combining industrial-grade responsiveness with the freedom of wireless connectivity — a clear leap over traditional wired solutions.

Why Go Wireless?

Conventional wired joysticks restrict movement, clutter workspaces, and are prone to cable fatigue over time. Sigma’s wireless solution offers seamless integration, untethered flexibility, and industrial reliability without compromising control precision.

Feature Comparison Table

Feature |

Sigma Wireless Joystick |

Traditional Wired Joystick |

Connectivity |

Wireless (Industrial-grade RF) |

Wired (USB / Serial) |

Mobility |

Fully mobile, no cable limit |

Limited by cable length |

Interference Resistance |

High – with signal encryption |

Medium – prone to EMI |

Setup Time |

Quick (plug & sync) |

Slower (manual cable routing) |

Workstation Clutter |

Minimal |

High (tangled or long cables) |

Battery System |

Rechargeable, 12+ hrs runtime |

N/A |

Signal Drop Risk |

Very Low (auto-reconnect) |

None (but cable wear risk) |

Maintenance |

Low (no cable wear) |

Higher (cable wear & damage) |

Integration with Sigomatic / Pro |

Seamless |

Compatible |

User Comfort |

Ergonomic & portable |

Static position, cable drag |

Summary

The Sigma Wireless Joystick redefines operator experience for modern laser systems. While wired joysticks still serve basic applications, they fall short in dynamic environments where flexibility, durability, and ease of use are paramount.

Upgrade to wireless and cut the cord — without cutting control.

Competitive AdvantagesWhy the Wireless Joystick Is a Smart Upgrade for Precision Laser System Control?

Unmatched Freedom, Precision Control

In modern laser welding and industrial automation, the ability to freely control motion without restrictive cabling is a serious advantage. The Sigma Wireless Joystick delivers high-precision manual input across multiple axes — without the clutter and limitations of wired connections.

Designed specifically for Sigma laser systems, this ergonomically engineered device provides smooth, intuitive control for laser heads, rotary axes, and other motorized modules. Whether you’re aligning workpieces, testing system responses, or setting up complex motion paths, this joystick brings accuracy, convenience, and true plug-and-play compatibility.

Key Benefits at a Glance:

- Wireless Operation: Say goodbye to tangled wires — enjoy clean, flexible movement with secure wireless transmission.

- Multi-Axis Control: Navigate X, Y, Z, and rotary axes with fine-tuned input via high-resolution sensors.

- Ergonomic Design: Lightweight, hand-friendly form factor for prolonged use without fatigue.

- Seamless Sigma Integration: Pairs instantly with Sigma systems — no drivers, no fuss.

- Rechargeable & Durable: Long-lasting battery life with industrial-grade build quality.

- Secure Signal Transmission: Robust connection with interference protection for demanding environments.

Control Without Constraints — Move Freely, Operate Precisely

Unlike traditional wired controllers, the Sigma Wireless Joystick empowers operators with total mobility and clean workspace management — crucial in high-precision tasks like micro-welding, alignment, and motion testing. Setup is near-instant, and operation is incredibly intuitive, allowing your team to stay focused on quality rather than technical friction.

Whether in a compact workstation or a large-scale production environment, this wireless controller removes barriers to productivity, speed, and accuracy — making it a must-have for modern, dynamic laser manufacturing lines.