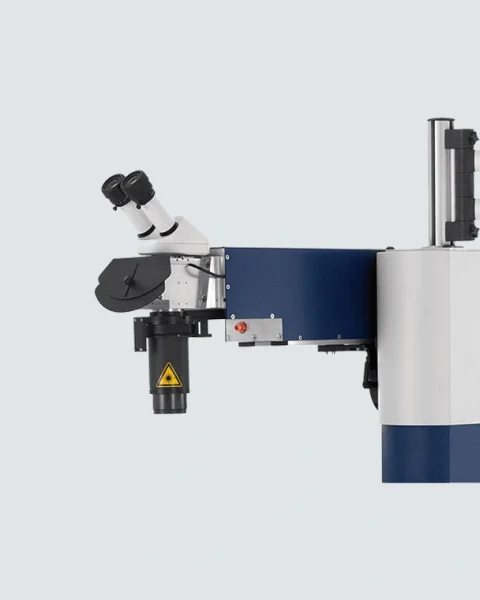

Upgrade Your FlexibilitySwivelling Wire Feed for Laser Welding

Precision Control for High-Performance Applications

Enhance your laser welding precision with Sigma Laser’s Swivelling Wire Feed – engineered for reproducible results, seamless software integration, and optimal control in medical and industrial production lines.

In the realm of industrial and medical laser welding, achieving consistent precision and production efficiency is non-negotiable. The Swivelling Wire Feed by Sigma Laser meets these demands with a robust and intelligent design tailored for advanced applications, including high-volume serial production and intricate weld tasks.

This high-performance accessory is powered by high-precision stepper motors, ensuring smooth and accurate wire delivery during the welding process. It is seamlessly integrated with Sigomatic Pro, Sigma Laser’s proprietary control software, offering full digital synchronization of feed speed, timing, and welding parameters.

Designed for flexibility and adaptability, the Swivelling Wire Feed is compatible with various wire diameters and supports precise feed control for even the most delicate jobs. Its patented wire straightening system ensures perfect wire alignment and minimizes feeding errors – a critical factor when dealing with micro-welding or narrow weld seams.

Whether you’re welding complex medical components or maintaining quality across large production batches, the Swivelling Wire Feed offers an all-in-one solution by uniting hardware, software, and control systems. This cohesive ecosystem reduces setup time, simplifies training, and boosts process stability, making it an indispensable upgrade for any high-end laser welding system.

Engineered to deliver consistent, high-precision wire feedingTechnical Specifications of Swivelling Wire Feed

The Swivelling Wire Feed from Sigma Laser is engineered to deliver consistent, high-precision wire feeding across a range of laser welding applications. Below is a breakdown of its technical features that ensure reliability, adaptability, and seamless integration with your laser system:

➤ Drive & Control System

- Motor Type: High-precision stepper motors

- Control Integration: Fully compatible with Sigomatic Pro software

- Motion Type: Continuous and precise wire feeding

- Swivel Capability: Manual or semi-automated swiveling for optimal positioning

➤ Wire Handling Capabilities

- Wire Straightening: Patented straightening technology to eliminate wire deformation

- Supported Wire Diameters: Multiple configurations available (e.g., 0.2 mm – 1.2 mm)

- Feed Accuracy: ±0.05 mm

- Feed Rate: Adjustable via software (precise feed rate control)

➤ Software Compatibility

- Primary Platform: Sigomatic Pro

- Features Supported: Real-time speed adjustments, feed delay sync, and wire diagnostics

- Control Interface: Intuitive UI via Sigomatic Pro with diagnostics and error handling

➤ Installation & Integration

- Connectivity: Plug-and-play integration into Sigma Laser systems

- Mounting: Modular design, adaptable to various laser system frames

- Power Requirements: 24 V DC

- Swivel Range: ±30° for angled or hard-to-reach welds

➤ Build & Materials

- Housing Material: Industrial-grade anodized aluminum

- Protection Rating: IP54 (dust and splash protection)

- Weight: 4.5 kg

Compatibility with Sigma Laser Systems

The Swivelling Wire Feed is engineered to seamlessly integrate with a wide range of Sigma Laser welding systems, enhancing precision and flexibility across various industries.

Fully Compatible With:

Sigma Laser System |

Compatibility Notes |

Sidanus Light |

Full integration via Sigomatic Pro for 3D welding |

Sirius Light |

Ideal for fine-detail welds and repetitive patterns |

Siega Light |

Supports complex assemblies with multi-axis motion |

Sidanus Fibre |

Optimized for high-speed fibre laser operations |

Sirius Fibre |

Recommended for precision medical & electronics |

Simass Base Unit |

Plug-and-play support for modular configurations |

Simass Rotate |

Syncs with rotational axis for uniform wire feed |

Simass Slide |

Ensures accurate feed during automated sliding |

Software Compatibility:

- Sigomatic: Partial compatibility (basic control features only)

- Sigomatic Pro: Full compatibility with advanced automation features

Integration Requirements:

- Requires Sigomatic-compatible control unit

- 24V DC power input

- Modular mechanical interface (mounting brackets included)

Where the Motor-Driven Rotary Device ExcelsIndustrial Applications of welding machine Swivelling Wire Feed

The Swivelling Wire Feed is a critical enhancement for laser welding systems where continuous and precise wire delivery is essential. Its versatility makes it ideal for a wide range of industrial sectors and complex geometries.

Medical Device Manufacturing

Ensures smooth and consistent wire feeding during the welding of small, delicate medical components, such as surgical tools and implants—where precision and consistency are critical.

Tool and Mold Repair

Supports consistent weld buildup in damaged molds or tooling surfaces, especially in curved or angled sections, thanks to the swivelling function.

Aerospace Structures

Applicable in welding lightweight but high-strength alloys used in aerospace parts where filler wire precision affects both integrity and performance.

Precision Electronics Welding

Ideal for micro-welding applications in electronics where controlled filler material flow is necessary to avoid overheating or damaging sensitive components.

Automotive Component Fabrication

Useful in the joining and buildup of fine structural elements like sensors, brackets, and metal housings in car manufacturing—especially when welding on inclined or confined surfaces.

Custom Fabrication and R&D

Supports flexibility in prototyping or low-volume production where part geometries frequently vary, requiring adaptive wire feed orientation.

Key Advantages Across Applications

- Precise control of filler material feed

- Enhanced weld repeatability and quality

- Supports complex geometries via ±30° swivel

- Integrates tightly with multi-axis movement

- Reduces material waste and operator fatigue

Configure to Fit Your Welding NeedsCustomization Options for Swivelling Wire Feed System In Welding

The Swivelling Wire Feed is designed not only for plug-and-play compatibility, but also for modular customization based on your specific welding needs. Whether you’re working with sensitive medical components or large industrial structures, the system adapts to your production environment.

Available Customization Options:

1. Wire Diameter Options

- Choose from multiple feeding nozzles for wire diameters ranging from 2 mm to 1.0 mm.

- Ideal for matching material deposition with application-specific requirements.

2. Swivel Range Adjustment

- Customize swivel angles beyond the standard ±30° to match unique part geometries or challenging access areas.

3. Mounting Configurations

- Different brackets and fixture types for mounting the wire feed on vertical, angled, or robotic axes.

- Ensures smooth wire delivery in both manual and automated workflows.

4. Extended Cable Lengths

- Extended data and power cables for flexible machine placement within large enclosures or gantry systems.

5. Sensor Integration

- Add-on support for wire speed monitoring sensors and break detection units, improving quality assurance in high-volume operations.

6. Software Customization (Sigomatic Pro)

- Preloaded parameters and integration templates for specific welding applications.

- Customize feed speed, retraction behavior, and synchronization with pulse or CW laser modes.

These customization capabilities make the Swivelling Wire Feed a scalable, future-proof solution that can evolve alongside your production needs.

FAQsFrequently Asked Questions

Answers to common questions about the welding machine swivelling wire feed

The system supports a wide range of wire diameters from 0.2 mm to 1.0 mm, allowing for fine control and precision across different material types and welding applications.

Yes, the Swivelling Wire Feed is fully compatible with both CW and pulsed lasers, and its parameters can be easily synchronized through the Sigomatic Pro software.

Absolutely. The standard swivel angle is ±30 degrees, but custom configurations are available depending on your part geometry and welding orientation.

The unit is delivered as a plug-and-play solution, fully calibrated for most Sigma Laser systems. Custom presets can be loaded through the software if needed.

Control is achieved via high-precision stepper motors, fully integrated with the Sigomatic Pro control interface. Users can set and modify wire feed speed, timing, and retraction dynamically.

Yes, the Swivelling Wire Feed is designed for easy retrofitting, with standard mounting brackets and plug-in connectivity compatible with most Sigma systems.

Helpful Guides & Articles for welding machine swivelling wire feed

Best Practices for Setup, Automation, and Precision Control

To help you get the most out of your Swivelling Wire Feed system, we’ve compiled essential guides and articles covering setup, operation, and optimization tips — all designed to maximize precision and productivity in your laser welding processes.

- How to Set Up and Calibrate Your Swivelling Wire Feed System

- The Role of Patented Wire Straighteners in Achieving Consistent Welds

- Integrating Swivelling Wire Feed with Sigomatic Pro Software: A Complete Guide

- Choosing the Optimal Wire Diameter for Medical and Series Production Applications

- Troubleshooting Common Wire Feed Issues and How to Fix Them

- Preventive Maintenance Tips to Extend the Life of Your Wire Feed

- Enhancing Reproducibility in Laser Welding with Advanced Wire Feeding Technology

- Best Practices for High-Precision Stepper Motor Control in Wire Feeding

- How Swivelling Wire Feed Improves Production Efficiency in Medical Technology

- Understanding Wire Feed Dynamics for Superior Weld Quality

Long-Term Support You Can Rely OnAfter-Sales Services of Swivelling Wire Feed

At Sigma Laser, our commitment to excellence doesn’t end at delivery. The Swivelling Wire Feed system comes with a full suite of after-sales services designed to ensure optimal performance, operator confidence, and long-term value from your investment. Whether you’re a small workshop or a multinational manufacturer, our support ecosystem keeps your production running smoothly.

Performance Optimization Consulting

For customers with high-throughput needs or complex applications, we offer:

- Process auditing

- Automation optimization

- Custom software macros

- Fixture design and integration consulting

Installation & Commissioning

Our team provides on-site setup, system calibration, and full integration into your existing workspace or automation line. We ensure everything is optimized from day one — including safety checks, software configuration, and trial welds.

Spare Parts & Consumables

We maintain a well-stocked inventory of Replacement lamps, Optical components, Cooling units and Wear parts. Fast shipping worldwide ensures minimal downtime.

Remote Diagnostics & Global Support

From preventive maintenance to rapid troubleshooting, our global service team keeps your laser welding equipment running with minimal downtime through on‑site visits and secure remote diagnostics.

Operator Training & System Onboarding

Hands‑on training programs give your staff the skills to operate, maintain, and optimize Sigma laser welding systems safely and productively right from day one.

Extended Warranty & Lamp Breakage Protection

Enjoy long‑term peace of mind with comprehensive warranty coverage—including exclusive lamp break protection—for all light‑pumped laser welding systems.

Keeping Your Swivelling Wire Feed in Peak ConditionMaintenance Instructions for welding machine swivelling wire feed

Proper maintenance ensures reliable performance, maximizes lifespan, and reduces downtime of your Swivelling Wire Feed system. Follow these guidelines to keep your equipment in top condition.

Daily Maintenance

- Visual inspection of the wire feed mechanism for dust, debris, or wire fragments.

- Check wire path for any obstructions or bends.

- Verify tension and alignment of wire straighteners.

- Ensure smooth joystick operation and responsiveness.

- Confirm proper software connection with Sigomatic Pro.

Weekly Maintenance

- Clean feed rollers and guides with a soft, lint-free cloth to remove accumulated dust and contaminants.

- Inspect stepper motors for unusual noises or vibration during operation.

- Lubricate moving parts lightly if recommended by manufacturer guidelines.

- Check wiring and connectors for secure attachment and signs of wear.

- Test emergency stop and safety interlocks for proper function.

Monthly Maintenance

- Deep clean wire straighteners to remove buildup and ensure optimal wire feeding.

- Calibrate wire feed speed and tension parameters in Sigomatic Pro software to maintain precision.

- Inspect and tighten all mechanical fasteners and mounts.

- Review software logs for any error patterns or warnings.

- Replace worn feed rollers or components as needed.

Long-Term Maintenance (Quarterly or Biannual)

- Full system diagnostic and performance check by trained technicians.

- Update Sigomatic Pro software to latest version for improved functionality and security.

- Inspect and replace stepper motors or sensors showing signs of degradation.

- Check cooling and ventilation systems to avoid overheating.

- Document maintenance activities and schedule upcoming service dates.

Tips for Professionals

- Keep a maintenance logbook to track all performed actions and observations.

- Use only Sigma-certified replacement parts to ensure compatibility and reliability.

- Train operators on correct wire loading and handling procedures to reduce mechanical wear.

- Schedule preventive maintenance before peak production periods to minimize risk of failures.

- Monitor system alerts and warnings proactively rather than reactively.

Summary

Regular maintenance of your Swivelling Wire Feed system — from daily inspections to long-term servicing — is critical to achieving consistent, high-quality welds and maximizing equipment uptime. Following these structured guidelines ensures you get the best performance and reliability from your investment over time.

Operating the Swivelling Wire Feed with ConfidenceSafety Guidelines of Swivelling Wire Feed system

Operating the Swivelling Wire Feed system in industrial laser welding environments requires strict compliance with safety protocols to protect operators, maintain equipment integrity, and ensure smooth, uninterrupted production. Follow these guidelines carefully during installation, operation, and maintenance.

Laser Safety Classification

The Swivelling Wire Feed is used as part of laser welding systems classified typically under Class 1 or Class 4, depending on the configuration:

- Operate within a fully enclosed Class 1 laser safety setup whenever possible.

- If working with open Class 4 lasers, ensure appropriate shielding, interlocks, and protective barriers are in place.

- Follow all relevant laser safety regulations and facility policies strictly.

Personal Protective Equipment (PPE)

Operators should wear the following PPE according to the task:

Task |

Recommended PPE |

Routine operation |

No PPE required under closed enclosure |

Maintenance (open casing) |

Laser safety goggles (rated for laser wavelength) |

Wire feed adjustments |

Protective gloves and sleeves |

Handling wire spools |

Cut-resistant gloves and safety shoes |

Optical inspection or cleaning |

Anti-static gloves and lint-free cloths |

Additional recommendations:

- Laser safety glasses rated for the specific laser wavelength in use.

- Protective clothing to minimize risk from sparks or hot materials.

- Steel-toe shoes to protect from heavy components.

Workspace Safety Requirements

- Keep the wire feed area clean and free of clutter, including cables and tools.

- Ensure adequate ventilation to extract fumes generated during welding.

- Mount the wire feed system on a stable, vibration-free surface.

- Maintain clear access to emergency stop buttons and power cutoffs.

Electrical & Cooling System Safety

- Verify that all electrical components are properly grounded before use.

- Regularly inspect cables for wear, damage, or loose connections.

- Avoid operating the system near liquids or in high-humidity environments.

- If cooling systems are integrated, maintain coolant levels and check for leaks regularly.

Software & Control Precautions

- Always verify software connection stability between the wire feed and the Sigomatic Pro control system.

- Avoid unintended wire feed movements by engaging control locks when the system is idle.

- Alert nearby personnel before initiating automated wire feeding or swivelling movements.

Emergency Procedures

- Use the emergency stop button immediately in case of unexpected wire feed motion, unusual noises, smoke, or sparks.

- Cut off power before performing any inspection or maintenance work.

- Follow your facility’s laser safety emergency and evacuation protocols promptly.

Training & Access Control

- Only trained and authorized personnel should operate or maintain the wire feed system.

- Operators must complete safety training covering laser system integration, software use, PPE requirements, and emergency procedures.

- Restrict access to the wire feed and welding area during operation using signage or physical barriers.

Safety Summary

The Swivelling Wire Feed system is a critical component in achieving consistent, high-quality laser welds. Ensuring operator safety and equipment longevity depends on strict adherence to these safety guidelines. Proper training, routine inspections, and compliance with laser safety standards will help maintain a safe, efficient welding environment.

Competitive ComparisonWhy the Swivelling Wire Feed Outperforms Conventional Wire Feeding Systems?

Wire feeding is a crucial element in laser welding, especially in high-precision and high-volume applications. The Swivelling Wire Feed from Sigma Laser sets itself apart from traditional wire feeding solutions through superior control, integration, and flexibility — all designed to maximize reproducibility and production efficiency.

Fully Integrated Control with Sigomatic Pro

Unlike many standalone wire feeders that require external controllers or manual adjustments, the Swivelling Wire Feed is seamlessly integrated with Sigma’s Sigomatic Pro software. This integration enables precise synchronization between wire feeding and laser welding parameters, reducing errors and optimizing process stability.

High-Precision Stepper Motor Drive

Conventional wire feeders often rely on basic motors with limited precision, causing inconsistent wire feeding and weld quality. The Swivelling Wire Feed utilizes high-precision stepper motors for smooth, reliable wire delivery and minimal variation, crucial in demanding fields like medical technology and series production.

Patented Wire Straightening Technology

Many wire feed systems lack effective straightening, resulting in wire jams or feeding inaccuracies. Sigma’s patented wire straighteners maintain optimal wire alignment and tension, reducing downtime and improving weld consistency.

Adaptable to Different Wire Diameters

While traditional feeders might only support a narrow range of wire sizes or require multiple hardware changes, the Swivelling Wire Feed is designed for flexibility across various wire diameters, minimizing changeover time and enabling multi-application use with minimal setup.

Competitive Comparison Table

Feature / Device |

Swivelling Wire Feed (Sigma) |

Conventional Wire Feed Units |

Manual Wire Feeding |

Software Integration |

Full integration with Sigomatic Pro |

External or no integration |

None |

Motor Drive Type |

High-precision stepper motors |

Basic DC or servo motors |

Manual |

Wire Straightening |

Patented wire straighteners |

Limited or none |

N/A |

Support for Multiple Wire Diameters |

Yes, flexible design |

Often limited or hardware-specific |

Manual handling |

Setup & Calibration |

Automated, software-controlled |

Manual or semi-automated |

Manual |

Best Use Case |

High-precision, series production |

General welding tasks |

Prototyping, low volume |

Whether you’re upgrading existing equipment or designing a new laser welding line, the Swivelling Wire Feed provides unmatched precision, ease of use, and process reliability — all essential for demanding industrial applications.

Competitive Advantages of the Swivelling Wire FeedWhy the Swivelling Wire Feed Is a Smart Upgrade for Precision Laser Welding Efficiency?

Precision Wire Feeding, Seamless Software Integration

In laser welding, consistent and precise wire feeding is essential to achieve flawless, repeatable welds—especially in demanding fields like medical technology and series production. The Swivelling Wire Feed delivers highly accurate wire control through advanced stepper motors and patented wire straightening technology, all fully integrated with Sigma’s Sigomatic Pro software.

Whether you’re working with fine wires for intricate welds or larger diameters for heavy-duty applications, this system ensures smooth, reliable feeding and optimal synchronization with your welding parameters—making it a perfect fit for precision-driven manufacturing.

Key Benefits at a Glance:

- High-Precision Stepper Motor Control: Ensures smooth and accurate wire feed speed for consistent weld quality.

- Patented Wire Straighteners: Maintain ideal wire tension and alignment, reducing jams and feeding errors.

- Seamless Software Integration: Full control and automation via Sigomatic Pro, minimizing manual adjustments.

- Flexible Wire Diameter Compatibility: Supports multiple wire sizes with minimal hardware changes.

- Ergonomic Swivelling Mechanism: Enables easy wire spool handling and positioning.

- One-Stop Shop Solution: Combines wire feed, control electronics, and software for simplified setup and maintenance.

- Industry Versatility: Ideal for medical device manufacturing, automotive, aerospace, and high-volume production lines.

Elevate Your Wire Feeding—Without Production Interruptions

Unlike traditional standalone wire feeders that require manual calibration or third-party controllers, the Swivelling Wire Feed is designed for quick integration and minimal downtime. Its user-friendly operation and tight software coupling allow you to ramp up production speed and quality with confidence.

Investing in this system means fewer feeding issues, faster changeovers, and enhanced reproducibility—all contributing to lower costs and higher throughput. The Swivelling Wire Feed is the precision wire feeding upgrade your laser welding process needs to stay ahead.