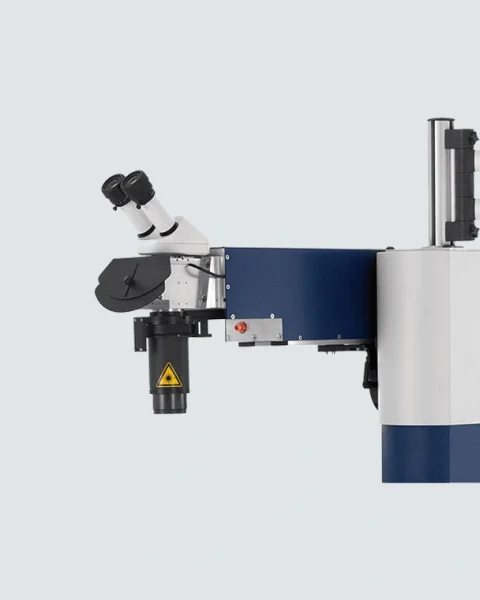

Upgrade Your FlexibilityMotor-Driven Rotary Device for Precise Rotational Laser Welding

The Motor-Driven Rotary Device adds high-precision rotation capability to your laser welding system—ideal for processing round and cylindrical components. With seamless integration and joystick-controlled movement, it enhances productivity without the need for complex retrofitting.

In advanced industrial laser welding, precision and flexibility are paramount—especially when handling cylindrical or round components such as pipes, shafts, or medical instruments. The Motor-Driven Rotary Device from Sigma Laser delivers continuous and reliable rotational movement, enabling seamless circumferential welds and 360-degree part handling.

Designed for effortless integration, this module comes with pre-installed drive and control systems, eliminating the need for complicated retrofitting or external interfaces. Operators can control the rotary motion directly via joystick, allowing for intuitive, real-time control over the welding process.

Whether you’re producing in automotive, aerospace, medical, or toolmaking, this motorized rotary unit ensures consistent results on rounded geometries. Plus, thanks to its three-jaw chuck (available in 80 mm or 160 mm sizes) and through hole capabilities (Ø 16 mm or Ø 40 mm), it accommodates a wide range of component sizes.

Advantages at a Glance

- Continuous Swivelling: Enables smooth rotational welding on circular parts.

- Three-Jaw Chuck Options: Available in 80 mm or 160 mm diameter sizes for flexible clamping.

- Through Hole Design: Allows for long component handling with diameters up to 40 mm.

- Plug-and-Play Integration: Built-in drive and control systems simplify implementation.

- Joystick Operation: Real-time manual control with precision positioning.

Engineered for precision, durability, and flexibilityTechnical Specifications of Motor-Driven Rotary Device

The Motor-Driven Rotary Device is engineered for precision, durability, and flexibility in industrial laser welding environments. Below is a comprehensive list of its key technical specifications to help you assess compatibility and performance.

Feature |

Specification |

Rotation Type |

Motor-driven continuous swivelling |

Control Interface |

Joystick-operated with real-time precision |

Drive System |

Integrated motor and controller (plug-and-play) |

Chuck Type |

Three-jaw chuck |

Chuck Sizes |

Ø 80 mm or Ø 160 mm (optional) |

Through Hole Diameter |

Ø 16 mm or Ø 40 mm (optional) |

Rotational Speed |

Adjustable via Sigomatic/Sigomatic Pro (if integrated) |

Mounting |

Direct system integration; no retrofitting required |

Welding Axis Compatibility |

Ideal for rotation of cylindrical workpieces across all laser systems |

Power Supply |

Fully integrated into Sigma Laser welding systems |

This unit ensures high torque, low backlash, and precise rotational alignment, making it ideal for industries where circular weld accuracy is critical—such as medical, aerospace, and high-performance tool manufacturing.

Compatibility: Seamless Integration with Sigma’s Modular Welding Systems

The Motor-Driven Rotary Device is designed to seamlessly integrate with a wide range of Sigma Laser welding platforms, enabling advanced rotational processing for cylindrical and tubular workpieces. Its plug-and-play design ensures quick setup without requiring additional configuration or retrofitting.

Compatible With:

Laser System |

Compatibility Level |

Notes |

Sidanus Light |

✅ Fully Compatible |

For small-to-medium cylindrical parts |

Sirius Light |

✅ Fully Compatible |

Ideal for detailed tube and wire welding |

Siega Light |

✅ Fully Compatible |

Works well with complex angular welds |

Sidanus Fibre |

✅ Fully Compatible |

High-speed, precision rotary control |

Sirius Fibre |

✅ Fully Compatible |

Perfect for high-output, automated production |

Simass Base Unit |

✅ Fully Compatible |

Designed for modular integration |

Simass Slide |

✅ Compatible (with optional extension) |

Suitable for large-diameter rotating parts |

Simass Rotate |

❌ Not Required |

Built-in rotation already present |

Not Compatible With:

- Entry-level manual systems without motor-driven axis support.

- Custom setups without joystick-based control.

The Motor-Driven Rotary Device provides exceptional versatility for industries requiring precise circular welds, such as medical tubing, aerospace assemblies, and rotationally symmetrical tool production.

Where the Motor-Driven Rotary Device ExcelsIndustrial Applications of the Motor-Driven Rotary Device (Welding Rotary Machine)

The Motor-Driven Rotary Device is engineered to enhance laser welding processes that involve cylindrical, tubular, or rotationally symmetric components. With precision-controlled rotation and seamless integration into Sigma systems, it’s ideal for industries demanding accuracy, repeatability, and multi-angle processing.

Medical Device Manufacturing

Precision welding of thin-walled stainless steel tubes, implant housings, and surgical instruments with rotational symmetry. The device allows continuous rotation for even energy distribution during circumferential welds.

Tool and Mold Making

Enables circular welding around rotating dies, mandrels, or cylindrical parts, ensuring high-strength joints with minimized heat distortion—vital for longevity and performance.

Jewelry and Watch Industry

Allows fine rotary positioning for decorative and functional welding on rings, cylindrical watch casings, and metal bracelets. Smooth rotation ensures precise bead placement.

Electrical & Sensor Housings

Facilitates reliable seam welding around cylindrical enclosures or connectors. Ideal for maintaining shielding integrity and mechanical protection in critical components.

Automotive Exhaust and Tubing

Perfect for welding pipes, flanges, and circular mounts in vehicle exhaust systems or hydraulic tubing, ensuring gas-tight and vibration-resistant connections.

Aerospace Components

Used for welding round structural parts such as nozzles, tubing, or sensor housings where uniformity, deep penetration, and heat control are critical for flight safety and reliability.

Key Advantages Across Applications

-

Precise Rotational Welding

Achieve consistent, circular weld seams with high repeatability, essential for cylindrical parts in medical, aerospace, and automotive industries. -

Enhanced Accessibility to Complex Geometries

The swivelling and motor-driven functionality enables flexible positioning, allowing welding on angled or hard-to-reach areas. -

Time-Efficient Processing

Reduces manual repositioning through automated rotation, significantly improving workflow and throughput in serial production. -

Minimal Heat Distortion

Controlled motion and even energy distribution minimize thermal impact—critical for delicate components in electronics or precision tools. -

Plug-and-Play Integration

Seamlessly integrates with existing Sigma laser welding systems without the need for extensive retrofitting, saving setup time and cost. -

Versatility Across Industries

Suitable for a wide range of sectors including medical technology, aerospace, tooling, and luxury goods, thanks to flexible chuck sizes and rotation control.

Configure to Fit Your Welding NeedsCustomization Options of The Motor-Driven Rotary Device for laser welding machines

The Motor-Driven Rotary Device from Sigma Laser is designed with modularity and flexibility in mind. To meet the varying demands of different industries and applications, it offers a range of customization options that enhance both its mechanical and software capabilities.

Chuck Size Variants

- Choose between a three-jaw chuck with an 80 mm or 160 mm diameter depending on the size and shape of your workpieces.

- Optional custom jaws for irregular or delicate components are available upon request.

Through-Hole Diameter

- Configure the device with a 16 mm or 40 mm through-hole, ideal for accommodating long tubular components such as pipes, rods, or cables.

Swivel Control Options

- Manual joystick control comes standard.

- Upgrade to programmable rotation sequences via Sigomatic or Sigomatic Pro for advanced automation workflows.

Software Integration

- Tailored integration with Sigomatic Pro enables synchronization with complex weld programs, including start-stop points, rotation angles, and torque control.

Mounting Orientation

- Can be factory-configured for either horizontal or vertical operation, or set up with a pivot mount for multi-axis functionality.

Retrofit Compatibility

- Already own a Sigma laser system? The rotary device can be retrofitted without complex modifications, reducing both cost and downtime.

Custom Branding and UI Options

- For OEM partners or high-volume customers, Sigma offers custom interface skinning, language localization, and branding options.

FAQsFrequently Asked Questions

Answers to common questions about the Motor-Driven Rotary Device of automated laser welding machines

The rotary device is designed for precise rotation and welding of round components such as pipes, rings, and shafts. It enables consistent rotational motion during laser welding operations, improving accuracy and finish quality.

Yes. The device is fully compatible with most existing Sigma systems and can be retrofitted without complex hardware changes, thanks to its integrated control and plug-and-play setup.

Yes. The motorized system supports continuous swiveling, which is essential for circular welds or multi-pass welding of cylindrical components.

It comes with two chuck size options (80 mm and 160 mm) and through-hole diameters of 16 mm and 40 mm, making it suitable for a wide range of component sizes and lengths.

The device integrates seamlessly with Sigomatic and Sigomatic Pro, enabling joystick control or fully automated rotation sequences.

Basic training is recommended for optimal use. However, the system is intuitive and user-friendly, and many customers find it easy to adopt with minimal instruction.

The device is suitable for rotating and welding a variety of materials, including steel, stainless steel, aluminum, and titanium, depending on the paired laser system.

Yes. Custom jaws and mounting configurations are available on request for non-standard or delicate workpieces.

Helpful Guides & Articles for Motor-Driven Rotary Devic

Best Practices for Setup, Automation, and Precision Control

Whether you’re new to Sigma Laser’s modules or looking to push your system to its full potential, these guides cover everything from installation to advanced automation workflows.

-

How to Set Up and Calibrate the Motor-Driven Rotary Device

Step-by-step guide for first-time setup, mechanical alignment, and software calibration with Sigomatic Pro. -

Choosing the Right Chuck Size for Your Application

A practical comparison between 80 mm and 160 mm chucks with use case examples. -

Optimizing Laser Welding of Cylindrical Components

Techniques and tips for achieving precise, high-quality welds on round parts using the rotary device. -

Retrofitting the Rotary Device on Existing Sigma Systems

A walkthrough on how to upgrade your older Sigma system with this device without needing external help. -

Integrating the Rotary Device with Sigomatic Pro Automation Workflows

How to create and control programmable rotation sequences for advanced welding tasks. -

Troubleshooting Rotation Irregularities and Calibration Errors

Common issues, error messages, and how to resolve them quickly. -

Maintenance Essentials for Long-Term Rotary Device Performance

Best practices for ensuring durability and reliability over years of industrial use. -

Safety Protocols for Using Rotary Devices in Laser Welding Environments

Key safety measures for operators handling rotating systems with high-precision lasers.

Long-Term Support You Can Rely OnAfter-Sales Services of Motor-Driven Rotary Device of laser welding machines

At Sigma Laser, our commitment to excellence doesn’t end at delivery. The Motor-Driven Rotary Device comes with a full suite of after-sales services designed to ensure optimal performance, operator confidence, and long-term value from your investment. Whether you’re a small workshop or a multinational manufacturer, our support ecosystem keeps your production running smoothly.

Performance Optimization Consulting

For customers with high-throughput needs or complex applications, we offer:

- Process auditing

- Automation optimization

- Custom software macros

- Fixture design and integration consulting

Installation & Commissioning

Our team provides on-site setup, system calibration, and full integration into your existing workspace or automation line. We ensure everything is optimized from day one — including safety checks, software configuration, and trial welds.

Spare Parts & Consumables

We maintain a well-stocked inventory of Replacement lamps, Optical components, Cooling units and Wear parts. Fast shipping worldwide ensures minimal downtime.

Remote Diagnostics & Global Support

From preventive maintenance to rapid troubleshooting, our global service team keeps your laser welding equipment running with minimal downtime through on‑site visits and secure remote diagnostics.

Operator Training & System Onboarding

Hands‑on training programs give your staff the skills to operate, maintain, and optimize Sigma laser welding systems safely and productively right from day one.

Extended Warranty & Lamp Breakage Protection

Enjoy long‑term peace of mind with comprehensive warranty coverage—including exclusive lamp break protection—for all light‑pumped laser welding systems.

Keeping Your Swivelling Y Axis in Peak ConditionMaintenance Instructions for the Swivelling Y Axis

Proper maintenance ensures long-term precision, smooth operation, and safety when using the Motor-Driven Rotary Device. The following guidelines provide structured checklists to cover daily, weekly, monthly, and long-term tasks, along with expert tips for professional users.

Daily Maintenance Tasks

-

Visual Inspection:

Check the rotary device and chuck for any signs of wear, dust, or misalignment. -

Clean the Chuck Surface:

Use a dry microfiber cloth or soft brush to remove debris and ensure smooth clamping. -

Check Cable Connections:

Ensure all signal and power cables are firmly plugged in and free from damage. -

Joystick Response Check:

Test the responsiveness of the joystick to confirm seamless control over rotation. -

Power Cycle Test:

Turn the device off and on to confirm smooth startup without system errors.

Weekly Maintenance Checklist

-

Lubricate Moving Parts:

Apply appropriate lubricant (as recommended in the user manual) to the motor bearings and rotational shafts. -

Inspect Chuck Jaws:

Check for alignment, smooth opening/closing, and any signs of corrosion or damage. -

Test Rotation Precision:

Run a sample part to verify the device rotates at the set speed and maintains positional accuracy. -

Software Integration Check:

Verify the device functions correctly with Sigomatic/Sigomatic Pro commands.

Monthly Maintenance Checklist

-

Tighten All Mounting Screws and Bolts:

Ensure structural stability and vibration-free operation during rotation. -

Clean Optical Sensors (if applicable):

If your configuration includes sensors, wipe them gently with optical-grade wipes. -

Check Chuck Through-Hole (Ø16 or Ø40 mm):

Remove blockages and test insertion/removal of elongated components. -

Electrical Check:

Use a multimeter to verify voltage levels are within operational specs (qualified personnel only).

Long-Term Preventive Maintenance (Every 6–12 Months)

-

Full Disassembly and Internal Cleaning:

Clean internal motor housings, inspect for dust buildup and apply fresh grease if needed. -

Recalibrate System with Sigomatic Pro:

Ensure alignment accuracy and update motion profiles if deviations are observed. -

Replace Worn Chuck Jaws or Bearings:

Replace any parts showing signs of fatigue or mechanical wear. -

Firmware/Software Update:

Update Sigomatic software and check compatibility with the device firmware.

Pro Maintenance Tips

-

Log Everything:

Maintain a digital or paper log of all maintenance tasks for auditing and predictive servicing. -

Rotate Chuck Jaws (if symmetrical):

To distribute wear evenly, rotate or switch jaws periodically. -

Use Dust Covers:

Protect the rotary device when not in use to avoid exposure to metal shavings or coolant spray. -

Train Technicians Properly:

Only allow trained personnel to perform motor or wiring diagnostics to prevent accidental damage. -

Check for Software Alerts:

Regularly review system logs and alerts from Sigomatic for predictive maintenance prompts.

Summary

By following this structured maintenance plan, the Motor-Driven Rotary Device will deliver:

- Consistent welding accuracy

- Extended hardware lifespan

- Reduced unexpected downtime

- Improved operator safety

Implementing these maintenance tasks will ensure that your investment performs at peak efficiency for years to come.

Operating the Motor-Driven Rotary Device with ConfidenceSafety Guidelines of Motor-Driven Rotary Device

Operating a motor-driven rotary system in industrial laser welding environments requires strict adherence to safety standards. The following guidelines help protect the operator, ensure system integrity, and reduce operational risks during installation, operation, and maintenance.

Laser Safety Classification

The Motor-Driven Rotary Device is used in conjunction with Class 1 or Class 4 laser systems depending on the machine setup:

- Ensure the system is fully enclosed (Class 1) or follow Class 4 laser safety procedures.

- Use proper interlocks and shielding if operating with high-power open lasers.

Personal Protective Equipment (PPE)

Operators must always wear:

- Laser Safety Glasses: Rated for the laser wavelength in use.

- Protective Gloves: To handle hot or sharp metal parts.

- Anti-static Clothing or Lab Coat: To avoid contamination and minimize sparks.

- Steel-toe Safety Shoes: For protection against dropped parts.

Task |

Recommended PPE |

Routine operation |

No PPE required under closed housing |

Maintenance (open casing) |

Laser safety goggles (1064 nm rated) |

Welding setup adjustments |

Safety gloves, protective sleeves |

Handling heavy components |

Safety shoes, cut-resistant gloves |

Optical cleaning or inspection |

Anti-static gloves and lens-safe cloths |

Workspace Safety Requirements

- Clear Work Zone: Keep the area around the rotary device free of tools, cables, and loose materials.

- Proper Ventilation: Ensure extraction systems are active to remove fumes from welding.

- Stable Mounting Surface: The rotary device must be mounted on vibration-free, secure bases.

- Emergency Stop Access: Always ensure the emergency stop button is easily reachable.

Electrical & Cooling System Safety

- Grounding: Verify the rotary device is properly grounded before operation.

- Cable Integrity: Inspect power and signal cables for wear or exposed wiring.

- Avoid Liquids: Never operate the system near spills or in high-humidity environments.

- Cooling Systems (if integrated): Maintain coolant levels and monitor for leaks if used alongside active laser systems.

Software & Control Warnings

- Joystick Safety: Avoid accidental joystick movement that could trigger the motor unexpectedly.

- Auto-Rotation Alerts: Always warn nearby personnel before initiating rotation.

- Sigomatic Sync: Confirm correct device connection and coordinate axis control via Sigomatic or Sigomatic Pro before executing automated tasks.

Emergency Procedures

-

Emergency Stop: Immediately press the E-STOP in case of:

- Unexpected movement

- Smoke, sparks, or unusual sounds

- Operator injury risk

- Power Cut: Turn off the main power switch before unplugging or inspecting the system.

- Evacuation: Follow facility-specific evacuation protocols if a laser or electrical emergency occurs.

Training & Access Control

- Only certified personnel should operate or maintain the rotary device.

- Ensure each operator has completed safety training on:

- Laser system integration

- Joystick controls

- PPE use and workspace setup

- Restrict access to the rotary station with signage or physical barriers when in use.

Safety Summary

The Motor-Driven Rotary Device from Sigma Laser enhances functionality and performance, but only when used responsibly. Following these safety measures:

- Protects your team

- Preserves equipment longevity

- Prevents costly operational errors

Adhering to certified training, regular inspections, and workplace safety standards is essential for a safe and productive welding environment.

Competitive ComparisonWhy the Motor-Driven Rotary Device Outperforms Conventional Systems?

While rotary axes are common in industrial welding setups, not all solutions are created equal. Here’s how the Motor-Driven Rotary Device from Sigma Laser outperforms conventional rotary systems — both in functionality and integration.

Integrated Control, No Retrofitting Headaches

Most third-party rotary units require extensive retrofitting, wiring, and software adjustments to communicate with the main welding system.

Sigma’s Motor-Driven Rotary Device, on the other hand, comes with pre-integrated drive and control electronics, allowing you to plug, calibrate, and start — with no need for redesigns or custom interfaces.

True Continuous Swivelling

Unlike step-index or limited-angle rotary units, this device supports smooth, continuous 360° rotation, ideal for complex seams and long welds on cylindrical parts — all controlled intuitively via joystick.

Designed for Long, Cylindrical Workpieces

With its through-hole design (Ø16 mm or Ø40 mm, depending on model), the unit easily accommodates long rods, tubes, or shafts — a major advantage over many rotary chucks that limit workpiece length.

Flexible Chucking Options

Equipped with a three-jaw chuck (available in 80 mm or 160 mm diameters), the device can secure a wide range of round parts without needing custom fixtures or adapters — saving time and setup costs.

Seamless Compatibility with Sigma Systems

Being part of the Sigma Laser ecosystem, this rotary device integrates natively with Simass platforms and Sigomatic controls, reducing potential points of failure and ensuring precise synchronized motion during welding.

Competitive Comparison Table:

Feature / Device |

Sigma Motor-Driven Rotary |

Third-Party Rotary Units |

Manual Rotary Fixtures |

Installation & Integration |

Plug & play, pre-integrated |

Requires custom integration |

Manual setup only |

Control System |

Integrated, joystick-operated |

External, may need interface |

None (manual control) |

Continuous Swivelling (360°) |

✅ Yes |

⚠️ Often limited or stepwise |

❌ Not supported |

Through-Hole for Long Components |

✅ Ø16 mm / Ø40 mm options |

⚠️ Varies, often limited |

❌ Usually solid chuck |

Chuck Flexibility |

3-jaw, 80 mm or 160 mm |

Often requires adapters |

Fixed or basic chuck |

Sigma System Compatibility (e.g., Sigomatic) |

✅ Native integration |

⚠️ May require modification |

❌ Not compatible |

Best Use Case |

Automated laser welding lines |

Semi-automated systems |

Prototyping, basic tasks |

Whether you’re upgrading an existing station or configuring a new one, the Motor-Driven Rotary Device delivers industrial-grade performance with unmatched simplicity — all without compromising your production flow.

Competitive Advantages of the Motor-Driven Rotary DeviceWhy the Motor-Driven Rotary Device Is a Smart Upgrade for Automated Laser Welding Precision?

Precision Rotation, Simplified Integration

In laser welding, the ability to precisely rotate round or tubular components can make the difference between an average weld and a flawless finish. The Motor-Driven Rotary Device adds powerful, joystick-controlled rotation to your setup — without the need for complex retrofitting or external control units.

Whether you’re welding shafts, rings, tubes, or precision mechanical parts, this motorized module delivers smooth, repeatable motion and perfect synchronization with your welding process — all in a compact, Sigma-compatible design.

Key Benefits at a Glance:

- Continuous Rotation: 360° motorized swivelling allows for seamless circumferential welding.

- Built-in Drive & Control: No separate controller needed — fully integrated electronics.

- Flexible Chucking Options: 3-jaw chuck available in 80 mm and 160 mm sizes.

- Long Part Support: Through-hole design supports components up to Ø40 mm in diameter.

- Joystick-Controlled Precision: Ergonomic manual control for fast positioning and fine adjustment.

- Retrofit-Friendly: Can be added to existing Sigma systems with minimal setup effort.

- Cross-Industry Use: Ideal for automotive, pipe welding, aerospace repair, toolmaking, and more.

Upgrade Your Rotary Capabilities — Without Downtime

Unlike traditional rotary add-ons, the Motor-Driven Rotary Device was designed with ease of use, fast deployment, and production scalability in mind. It eliminates the friction of external integration and delivers industrial-grade performance with zero learning curve.

Investing in this upgrade means more consistent welds, faster changeovers, and the freedom to handle more complex geometries — all without disrupting your current workflow. It’s the rotary axis your production line has been waiting for.